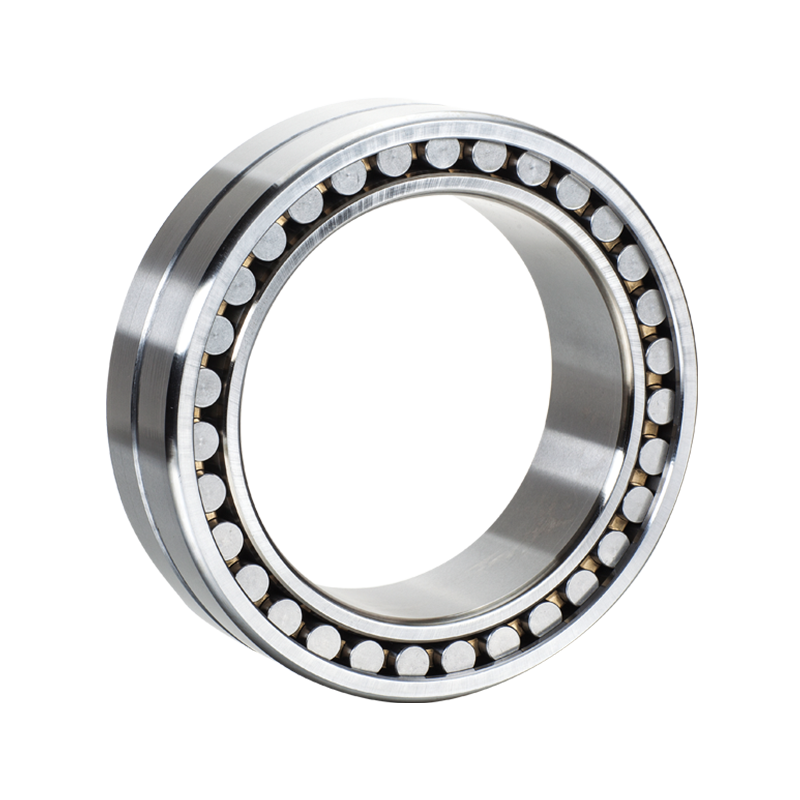

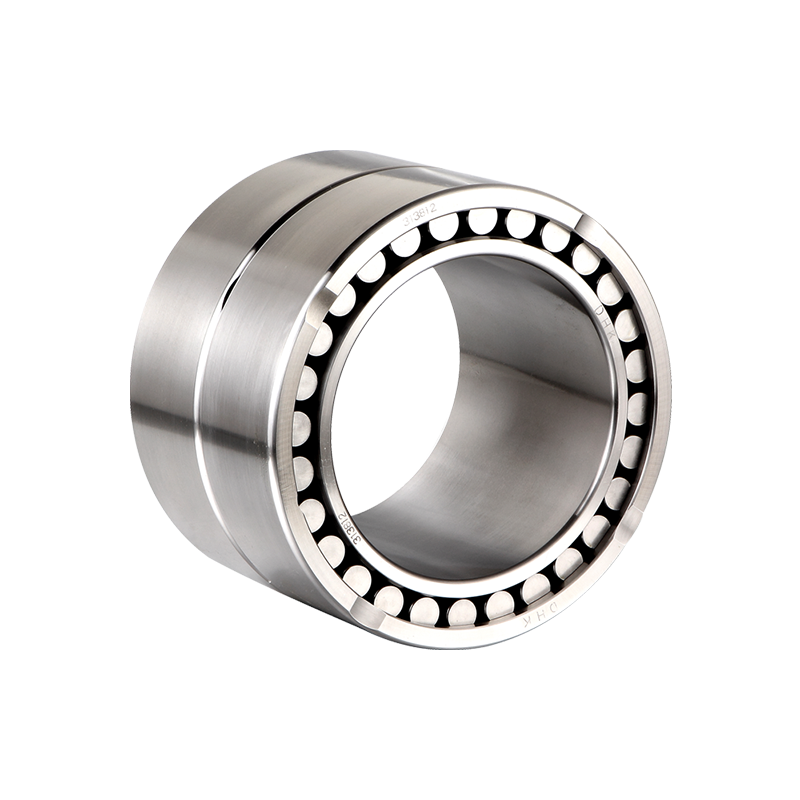

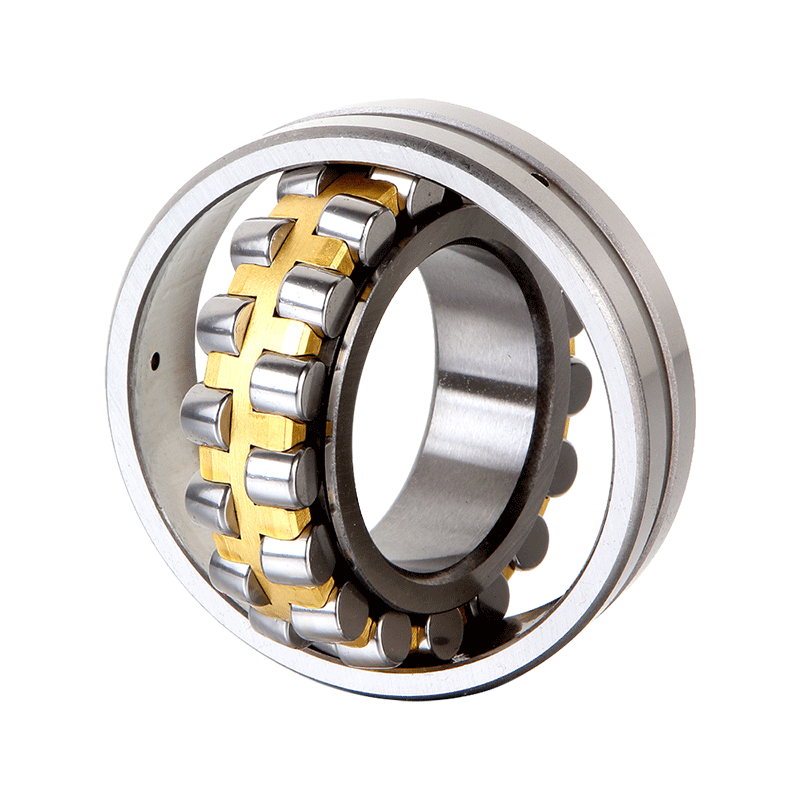

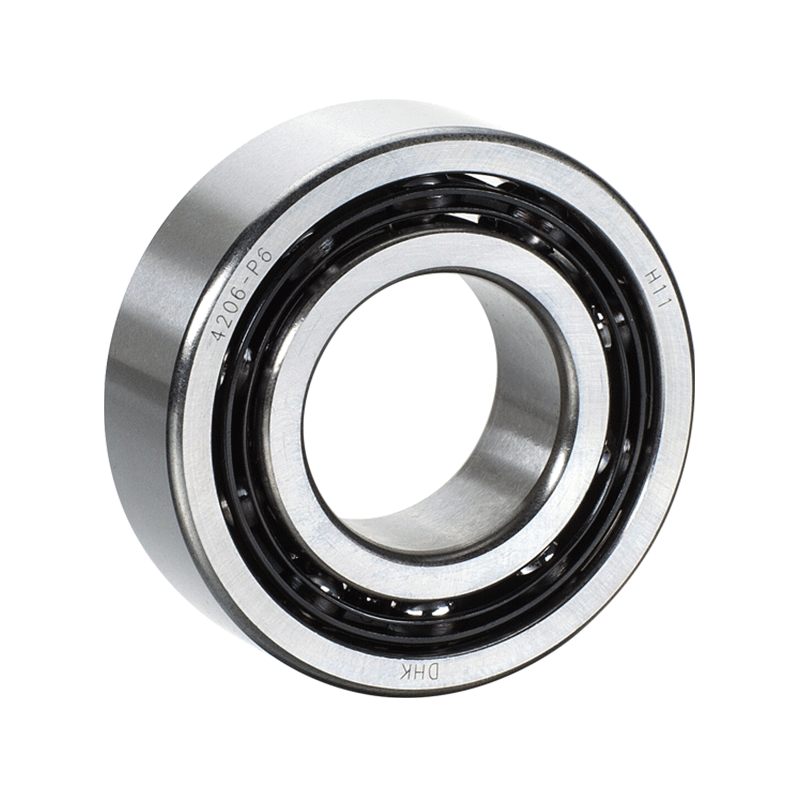

Four Row Cylindrical Roller Bearings are specifically designed to handle both large radial and axial loads simultaneously, making them ideal for heavy-duty applications. The unique configuration, with four rows of cylindrical rollers, allows for superior load distribution across a greater surface area compared to traditional single or double-row bearings. This increased load-carrying capability is essential in industries such as steel manufacturing, mining, cement production, and heavy construction equipment, where machinery is subjected to extreme forces. The enhanced load capacity enables these bearings to support the high radial and axial forces commonly found in large machinery like crushers, mills, and conveyor systems, improving the overall reliability and performance of the system.

The design of Four Row Cylindrical Roller Bearings significantly reduces wear and tear under high-load conditions, directly contributing to increased durability and longer service life. The multiple roller rows in these bearings ensure that the load is more evenly distributed, preventing localized stress concentrations that could lead to premature failure. The geometry of the rollers, combined with optimized material selection (typically high-carbon chromium steel or specialized alloys), allows these bearings to withstand heavy-duty loads and harsh operating conditions without losing performance over time. This durability is critical in reducing downtime and minimizing the need for frequent replacements, especially in applications with high operational demands such as rolling mills, mining machinery, and large turbines.

Four Row Cylindrical Roller Bearings provide exceptional stability under both radial and axial loads, making them highly suitable for applications that require reliable performance in the presence of large and varying forces. This makes them indispensable in systems where both types of forces act simultaneously, such as vertical shafts in wind turbines, large industrial gearboxes, and heavy-duty pumps. Their ability to balance axial and radial forces with precision ensures that rotating components remain aligned and maintain optimal operational efficiency. In applications such as paper mills and large crushers, where equipment may experience both heavy radial loads and significant axial thrust, the enhanced stability offered by these bearings prevents misalignment and ensures smooth operation.

One of the key benefits of Four Row Cylindrical Roller Bearings is their ability to operate reliably with minimal maintenance. The robust design, combined with the even distribution of forces across the bearing surfaces, reduces the likelihood of component failure due to factors such as misalignment, shock loads, or vibration. As a result, these bearings experience less wear and are more resistant to the stresses that commonly lead to failure in traditional bearing types. For industries that rely on continuous operation—such as the energy sector or large-scale manufacturing—minimizing maintenance costs and downtime is crucial. These bearings contribute to enhanced system reliability, reducing the frequency of bearing replacements and minimizing unplanned maintenance interventions, which in turn leads to lower overall operating costs.

Four Row Cylindrical Roller Bearings are known for their high rigidity, which makes them ideal for applications that require precise movement and minimal deformation under load. This rigidity is particularly important in applications where machinery operates under stringent tolerance requirements. Industries such as automotive manufacturing, aerospace, and precision machining depend on bearings that can maintain tight tolerances, ensuring that moving parts function smoothly and accurately. The high rigidity provided by these bearings ensures that rotating components maintain precise positioning, which is critical for the performance and longevity of precision machinery, such as CNC machines, turbine generators, and machine tools.

English

English Deutsch

Deutsch