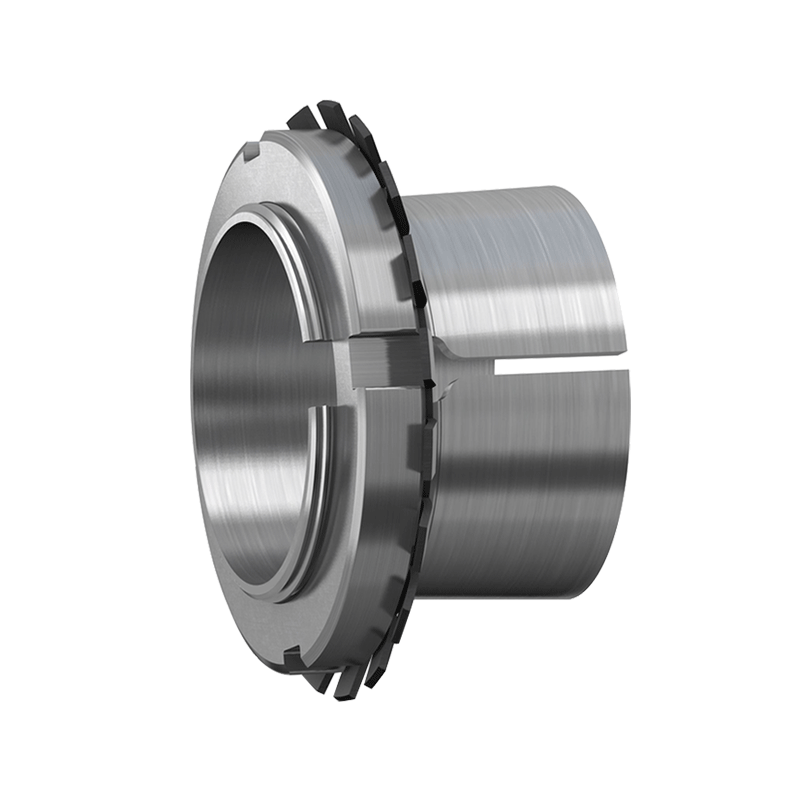

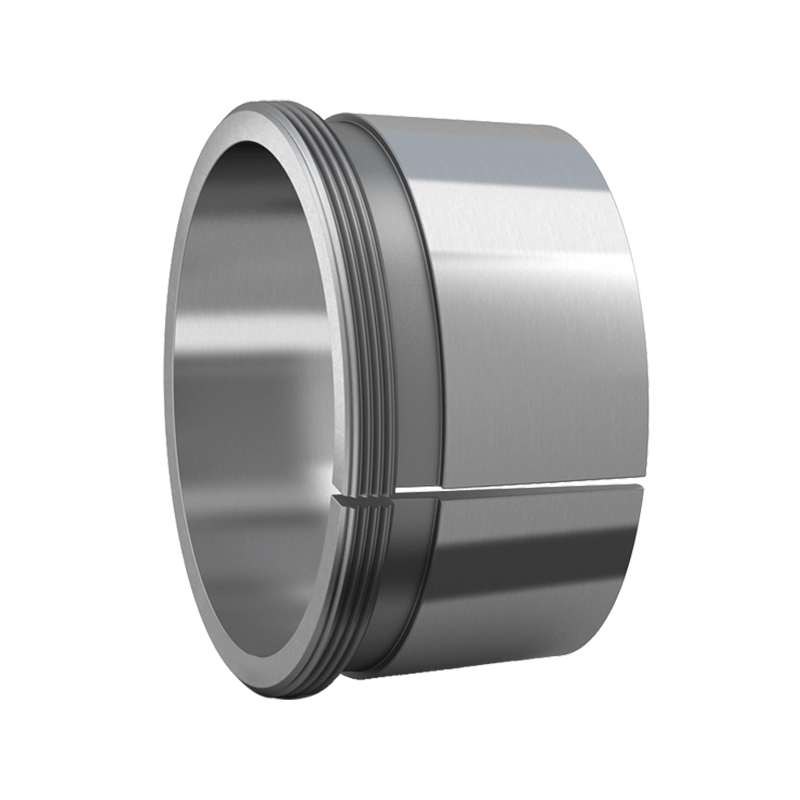

Secure Locking Mechanism: Radial insert ball bearings with eccentric locking collars are engineered to provide a robust and secure attachment to the shaft. The eccentric collar design, which features an off-center cam, engages firmly with the shaft when rotated, creating a tight fit. This mechanism effectively prevents the bearing from slipping or shifting on the shaft, even under high-torque conditions. This secure locking is crucial in applications where consistent performance is essential, as it ensures the bearing remains in the correct position during operation.

Ease of Installation: One of the most significant advantages of this bearing type is the simplicity of installation. The eccentric locking collar allows for quick and efficient installation without the need for additional components such as set screws or external locking devices. The collar is rotated in a specific direction to engage the shaft, and once locked, it remains in place. This ease of installation reduces downtime and labor costs, making these bearings particularly appealing in situations where speed and efficiency are critical.

Reduced Maintenance Requirements: Radial insert ball bearings with eccentric locking collars are designed for durability and longevity, requiring minimal maintenance once installed. The locking mechanism's resistance to loosening, even under conditions of vibration or dynamic loading, means that frequent adjustments are not necessary. This characteristic is particularly beneficial in industrial environments where equipment reliability is paramount, as it reduces the need for regular maintenance checks and interventions, thus lowering overall operational costs.

Vibration and Noise Reduction: The eccentric locking collar not only secures the bearing but also contributes to the overall stability of the system. By minimizing shaft movement within the bearing, it helps dampen vibrations that could otherwise propagate through the machinery. This reduction in vibration leads to smoother operation, which in turn reduces noise levels. In industrial applications where noise pollution is a concern, or where precision machinery is involved, the use of these bearings can enhance operational efficiency and workplace safety by minimizing disruptive noise.

Extended Service Life: The secure fit achieved by the eccentric locking collar minimizes the risk of shaft wear and bearing misalignment, two common causes of premature bearing failure. By maintaining proper alignment and reducing mechanical stress on the bearing components, the service life of the bearing is significantly extended. This longevity is particularly valuable in industrial applications where bearing replacement can be costly and time-consuming, as it reduces the frequency of replacements and associated downtime.

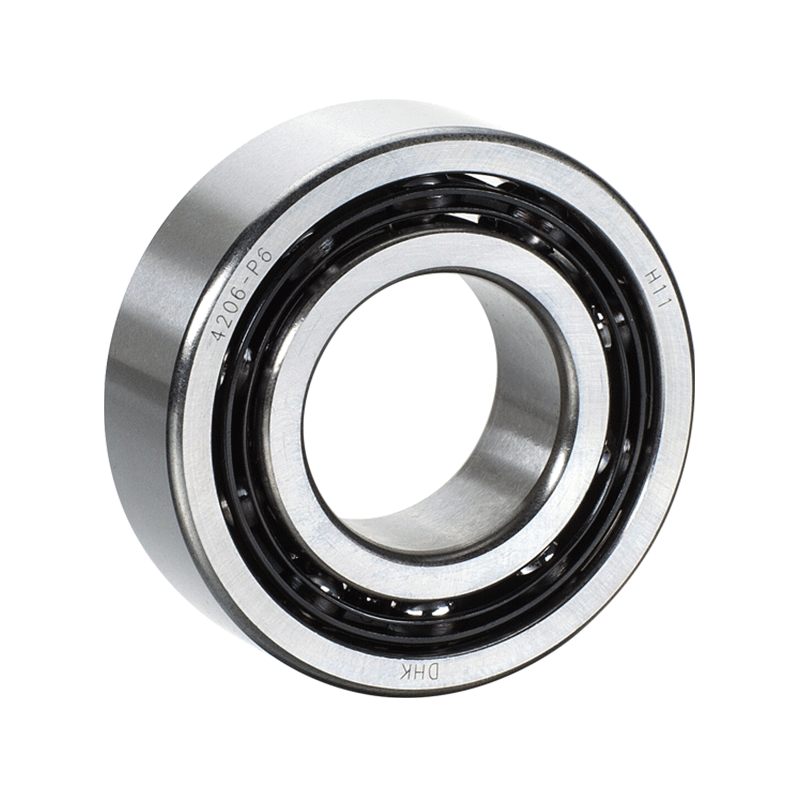

Versatility in Application: Radial insert ball bearings with eccentric locking collars are designed to accommodate slight misalignments between the shaft and the housing. This flexibility is a distinct advantage in applications where perfect alignment is challenging to achieve or maintain. The ability to tolerate misalignment without compromising performance makes these bearings suitable for a wide range of industrial applications, including those involving complex or variable load conditions, such as conveyor systems, agricultural machinery, and material handling equipment.

High Load Capacity: These bearings are engineered to handle both radial and axial loads, making them ideal for applications that involve combined loading scenarios. The eccentric locking collar ensures that the bearing can maintain its performance under varying load conditions, providing reliable operation in demanding industrial environments. The high load capacity of these bearings is essential in applications where the equipment is subjected to heavy or fluctuating loads, ensuring consistent and dependable performance.

Radial Insert Ball Bearings With Eccentric Locking Collar

English

English Deutsch

Deutsch