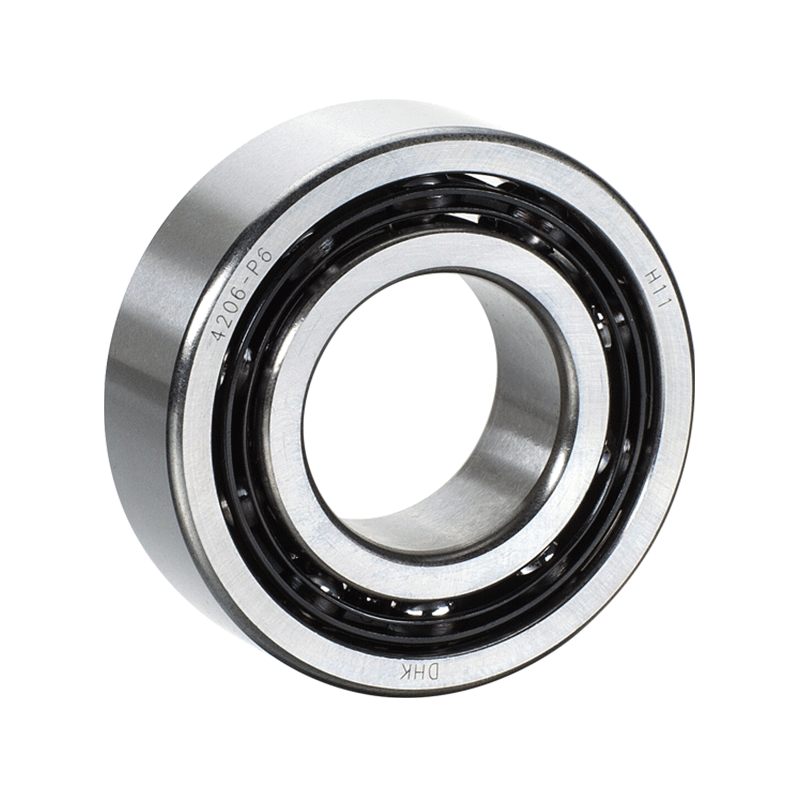

Seals and shields in agriculture machinery bearings serve crucial roles in protecting the bearings from contaminants and ensuring optimal performance. Here’s how they contribute:

Contaminant Protection: Agriculture machinery operates in environments where dust, dirt, mud, and agricultural chemicals are prevalent. Seals and shields serve as robust barriers that prevent these contaminants from infiltrating the bearing's internal components. Contact seals, for example, use lip seals that create a physical barrier against particles, while non-contact seals like labyrinth seals utilize intricate pathways to redirect contaminants away from critical areas. By effectively sealing the bearing housing, seals and shields mitigate the risk of abrasive particles entering bearing races, rollers, or balls. This protection is crucial as contaminants can accelerate wear, increase friction, degrade lubricants, and ultimately lead to premature bearing failure. By maintaining a clean internal environment, seals and shields ensure consistent bearing performance and extend the bearing's operational life.

Lubrication Retention: Proper lubrication is essential for reducing friction, heat generation, and wear within bearings. Seals and shields play a pivotal role in retaining the bearing lubricant by sealing it inside the bearing assembly. Contact seals feature elastomer materials that provide a tight seal around the bearing's rotating elements, preventing lubricant leakage even under high rotational speeds and loads. Non-contact seals, such as gap seals or labyrinth seals, maintain a barrier against contaminants while allowing for minimal frictional resistance, thus preserving the lubricant's integrity. Effective lubrication not only enhances bearing efficiency but also contributes to smoother operation, reduced energy consumption, and prolonged service intervals between maintenance tasks.

Extended Maintenance Intervals: Agriculture machinery often operates in remote or challenging environments, making regular maintenance a logistical challenge. Seals and shields contribute significantly to extending maintenance intervals by protecting the bearing from external contaminants and retaining lubrication. This reduces the frequency of bearing inspections, relubrication, and replacements, thereby lowering downtime and maintenance costs associated with agricultural equipment. Sealed and shielded bearings are designed with robust materials and configurations that withstand harsh environmental conditions, ensuring reliable performance over extended operational periods without compromising operational efficiency.

Environmental Resilience: Agriculture machinery encounters diverse environmental conditions, including exposure to moisture, rain, high temperatures, and abrasive particles. Seals and shields enhance the bearing's resilience by providing an additional layer of defense against these elements. Contact seals utilize lip seals or axial seals that tightly seal the bearing housing, effectively blocking water ingress and preventing lubricant washout. Non-contact seals, such as labyrinth seals, feature intricate designs that create a tortuous path for contaminants, preventing them from reaching critical bearing surfaces. This environmental resilience is critical for maintaining consistent performance and reliability of agriculture machinery bearings, even in demanding operational environments where exposure to contaminants could compromise bearing integrity and performance.

Radial Insert Ball Bearings Without Eccentric Locking Collar

English

English Deutsch

Deutsch