Proper bearing lubrication is crucial for ensuring the smooth operation and longevity of agricultural machinery for several reasons:

Reduced Friction: Lubrication is the lifeblood of bearing functionality, facilitating smooth motion by creating a thin film that separates moving parts. This film minimizes direct metal-to-metal contact between rolling elements and races, significantly reducing frictional resistance. By doing so, lubrication mitigates wear and tear on bearings, enhancing their operational lifespan and preserving critical tolerances within machinery components. This reduction in friction also translates to improved energy efficiency, as less power is required to overcome mechanical resistance, leading to lower operational costs and heightened sustainability in agricultural operations.

Heat Dissipation: In the dynamic environment of agricultural machinery, where heavy loads and high speeds are commonplace, the generation of heat due to friction is inevitable. Proper lubrication plays a pivotal role in managing this heat buildup by acting as a thermal conductor, transferring excess heat away from bearing surfaces and dissipating it into the surrounding environment. By maintaining optimal operating temperatures, lubricants prevent thermal degradation of bearing materials and lubricant breakdown, thereby preserving the structural integrity and performance characteristics of agricultural machinery components. This thermal management not only extends component lifespan but also ensures consistent operational efficiency under varying load and speed conditions.

Protection Against Contaminants: Agriculture presents a myriad of environmental challenges, from airborne dust and soil particles to moisture, fertilizers, and chemical agents. Without adequate protection, these contaminants can infiltrate bearing assemblies, compromising lubricant integrity and accelerating wear processes. Properly formulated lubricants serve as a barrier against contamination, forming a protective shield that prevents foreign particles from reaching critical bearing surfaces. Advanced lubricant additives, such as detergents and dispersants, actively combat the formation of harmful deposits, ensuring uninterrupted machinery performance and minimizing the risk of premature failure due to abrasive wear or chemical degradation.

Corrosion Prevention: The corrosive effects of moisture, chemical exposure, and atmospheric pollutants pose significant challenges to agricultural machinery reliability and longevity. Lubricants fortified with corrosion inhibitors provide essential protection against rust and oxidation, safeguarding bearing surfaces and prolonging equipment lifespan in corrosive environments. These inhibitors form a molecular barrier that actively repels moisture and neutralizes corrosive agents, preventing the onset of corrosion and preserving surface integrity. This corrosion protection is particularly critical for bearings operating in outdoor or exposed applications, where prolonged exposure to harsh environmental conditions can compromise equipment performance and safety.

Noise Reduction: Agricultural machinery noise emissions not only affect operator comfort but also have implications for environmental compliance and community relations. Proper bearing lubrication contributes to noise reduction by minimizing friction-induced vibrations and mechanical disturbances within bearing assemblies. This damping effect attenuates noise levels, creating a quieter operating environment that enhances operator productivity and promotes a more harmonious relationship with neighboring communities. Reduced noise emissions signify optimized machinery performance and energy efficiency, reflecting positively on the professionalism and environmental stewardship of agricultural operations.

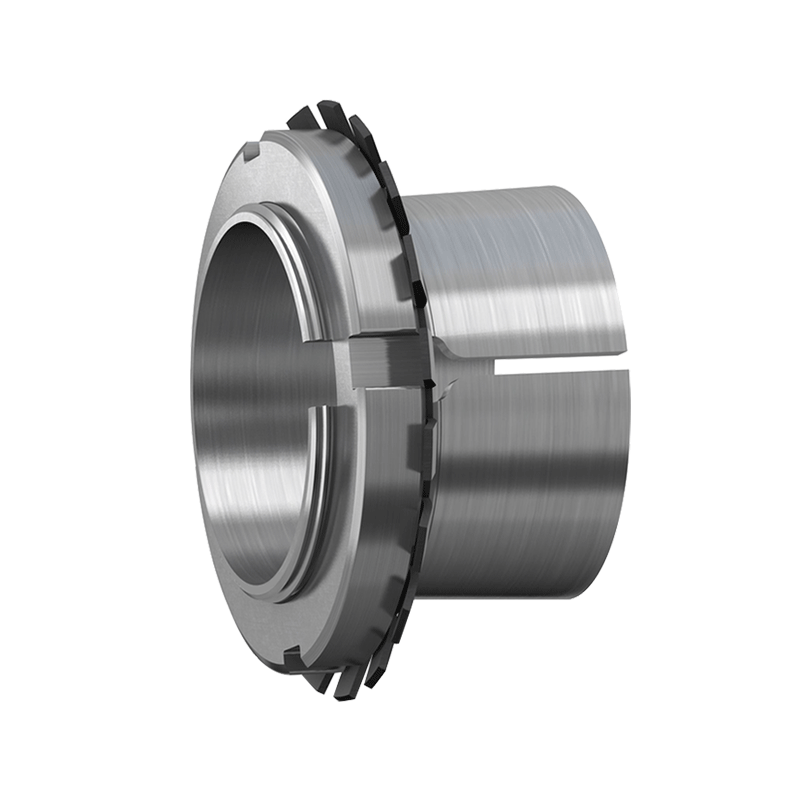

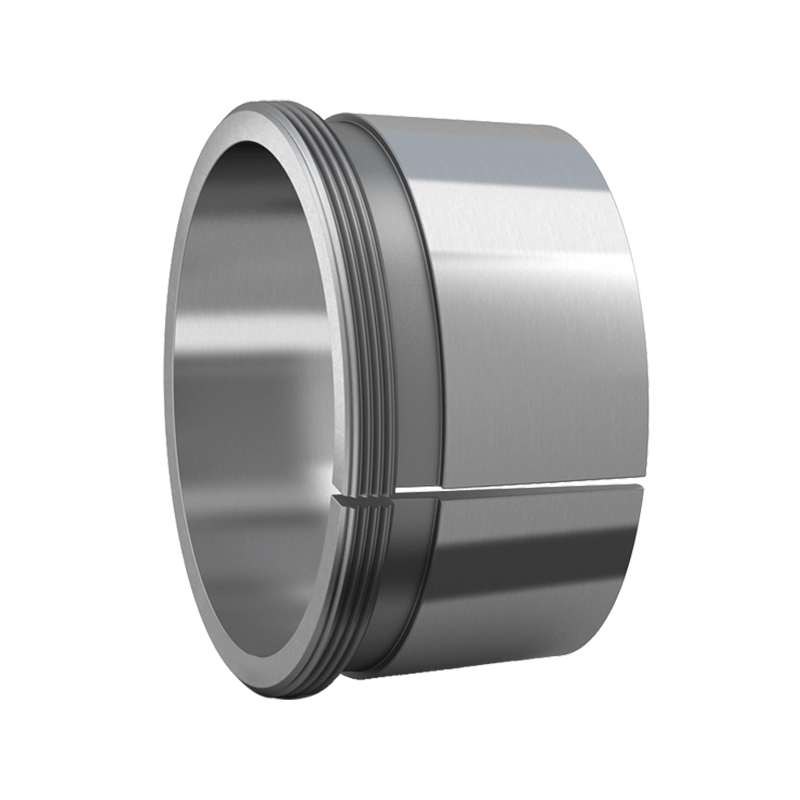

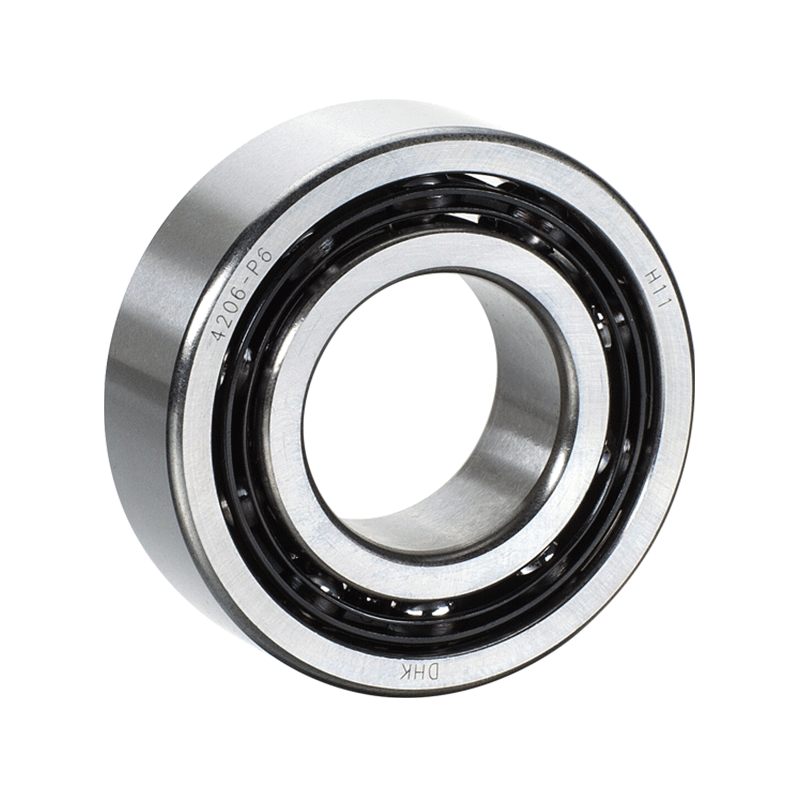

Radial Insert Ball Bearings Without Eccentric Locking Collar

DHK insert ball bearings usually have an extended inner rings, which make it possible of use an eccentric locking collar to locate the bearings on the shaft.

English

English Deutsch

Deutsch