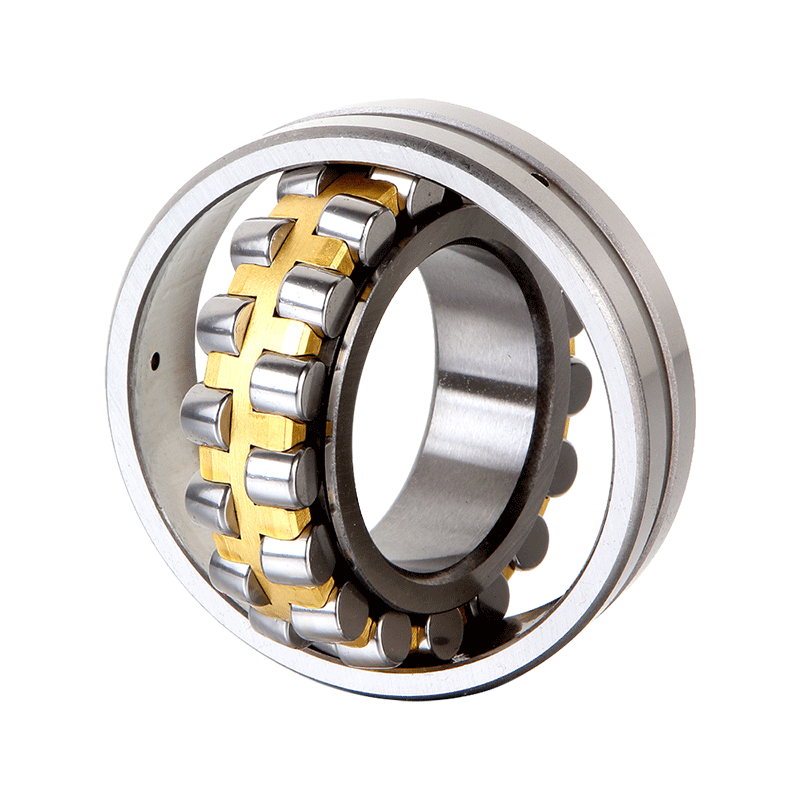

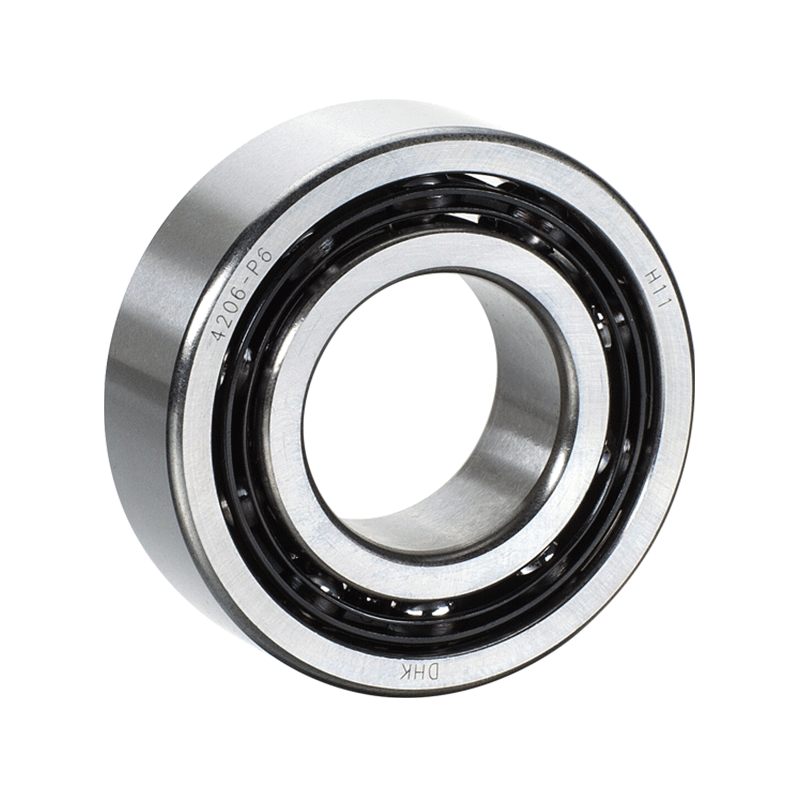

The internal clearance of double row angular contact ball bearings plays a crucial role in their performance and suitability for various operating conditions. Here's how:

Load Distribution: The internal clearance of double row angular contact ball bearings significantly influences the distribution of loads within the bearing assembly. Clearance ensures that the rolling elements make proper contact with the raceways, distributing loads evenly. Excessive clearance can bring about micro-movement of the rolling elements, resulting in localized stress concentrations and premature wear. Conversely, insufficient clearance can restrict movement, causing increased friction and potential overheating. Properly adjusted clearance ensures uniform load distribution, bearing lifespan and performance.

Temperature Management: Effective lubrication is essential for managing temperatures within the bearing assembly. The internal clearance directly impacts the volume of space available for lubricant circulation. Adequate clearance facilitates proper lubricant flow, ensuring effective heat dissipation during operation. This is particularly critical in high-speed or high-temperature applications where excessive heat can bring about lubricant breakdown, bearing damage, and ultimately, machinery failure. By maintaining proper internal clearance, manufacturers can optimize temperature management, enhancing bearing reliability and longevity.

Operating Noise: The internal clearance of double row angular contact ball bearings influences the amount of contact between the rolling elements and raceways. Excessive clearance can result in increased vibration and noise levels as the rolling elements impact the raceways with greater force. Conversely, insufficient clearance may bring about metal-to-metal contact, generating undesirable noise and potentially damaging the bearing components. Properly adjusted clearance minimizes frictional forces and vibration, reducing operating noise levels and enhancing the overall efficiency and comfort of the working environment.

Preload Adjustment: In precision applications where stiffness and rigidity are critical, such as machine tool spindles, achieving the appropriate preload is essential. Internal clearance adjustments can be used to precisely control the amount of preload within the bearing assembly. By optimizing the clearance, manufacturers can achieve the desired level of preload, ensuring performance under varying axial and radial loads. This enhances the precision, accuracy, and repeatability of the machinery, ultimately improving productivity and quality in manufacturing processes.

Operating Speed: Frictional forces within the bearing assembly directly influence its operating speed capability. The internal clearance plays a crucial role in minimizing frictional losses and optimizing bearing efficiency. Properly selected clearance reduces resistance to motion, enabling smoother operation and higher operating speeds. This is particularly advantageous in applications where speed is a critical performance parameter, such as aerospace, automotive, and industrial machinery. By optimizing internal clearance, manufacturers can maximize the operating speed of double row angular contact ball bearings without compromising performance or reliability.

Temperature and Environmental Variations: Double row angular contact ball bearings are exposed to a wide range of operating temperatures and environmental conditions during their service life. Changes in temperature can affect the dimensional stability of bearing components, potentially compromising performance and reliability. Proper internal clearance selection takes into account the thermal expansion and contraction of materials, ensuring consistent performance across varying temperature and environmental conditions. By maintaining clearance, manufacturers can enhance the resilience of double row angular contact ball bearings to temperature fluctuations, humidity, contaminants, and other environmental factors, improving overall reliability and longevity in diverse operating environments.

Double Row Angular Contact Ball bearings

English

English Deutsch

Deutsch