Bearing seals and shields play crucial roles in preventing contamination and retaining lubrication in engineering machinery applications:

Contamination Prevention: Bearing seals and shields act as robust barriers against a wide array of contaminants that can infiltrate machinery components. These contaminants include dust, dirt, water, chemicals, and other particles present in industrial environments. Seals and shields are engineered to form tight seals around the bearing components, ensuring that even the smallest particles are kept out. They achieve this by utilizing materials with excellent sealing properties and employing innovative designs that minimize gaps and entry points. By effectively blocking contaminants from entering the bearing housing, seals and shields mitigate the risk of abrasive wear, corrosion, and other forms of damage that can compromise bearing performance and lifespan.

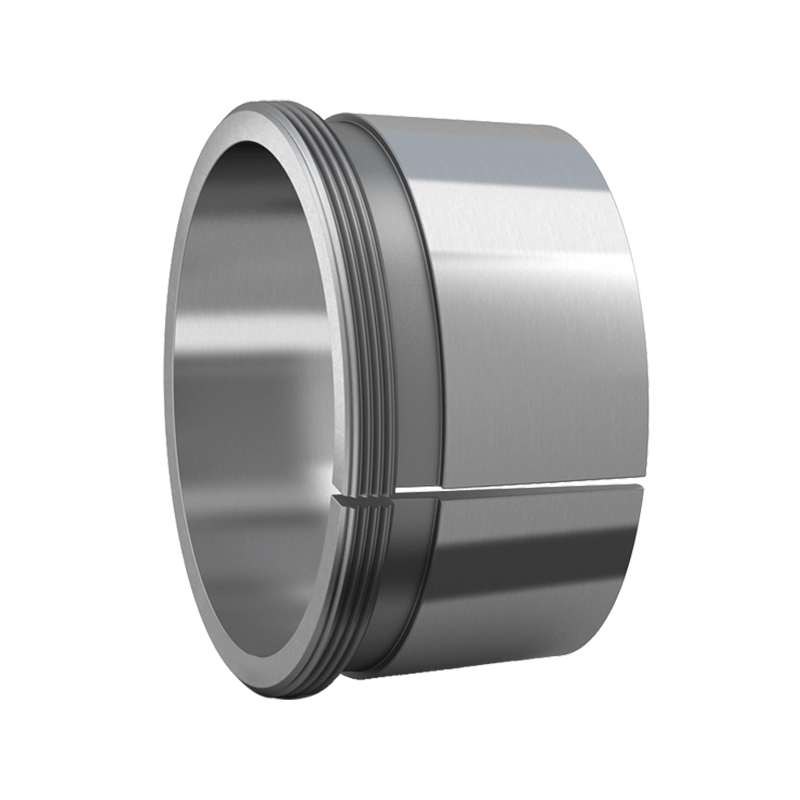

Lubrication Retention: Bearing lubrication is essential for reducing friction, dissipating heat, and preventing metal-to-metal contact between rolling elements and raceways. Seals and shields play a crucial role in maintaining optimal lubrication levels within the bearing by preventing the escape of lubricant and blocking the entry of external substances that could contaminate or degrade the lubricant. They achieve this through advanced sealing technologies such as lip seals, labyrinth seals, and contact seals, which create robust barriers against lubricant leakage and external contamination. Additionally, some seals and shields are designed to incorporate grease channels or reservoirs, which help replenish and redistribute lubricant during operation, ensuring continuous lubrication of critical bearing components.

Extended Service Life: The effective sealing and lubrication retention provided by bearing seals and shields contribute to significantly extending the service life of bearings in engineering machinery applications. By protecting the internal components from contamination and ensuring proper lubrication, seals and shields help minimize wear, fatigue, and other forms of damage that can lead to premature failure. This extended service life translates into reduced maintenance requirements, lower replacement costs, and increased uptime for the machinery, ultimately delivering significant cost savings and operational efficiencies for users.

Environmental Protection: Engineering machinery often operates in demanding environments where exposure to moisture, chemicals, abrasive particles, and other harsh elements is common. Seals and shields provide critical protection against these environmental factors, helping to maintain the integrity and performance of bearings in adverse conditions. They are designed to withstand extreme temperatures, chemical exposure, high-pressure washdowns, and other environmental challenges, ensuring reliable operation even in the most demanding industrial settings. Additionally, some seals and shields incorporate special features such as corrosion-resistant coatings, anti-wear materials, and enhanced sealing geometries, further enhancing their ability to withstand harsh environmental conditions and prolonging the lifespan of bearings in engineering machinery applications.

Enhanced Performance: The superior sealing and lubrication retention capabilities of modern bearing seals and shields contribute to enhanced performance and efficiency in engineering machinery applications. By minimizing friction, wear, and the risk of contamination-induced damage, seals and shields help optimize the operation of bearings, resulting in smoother, quieter, and more reliable machinery performance. This improved performance translates into higher productivity, reduced energy consumption, and improved product quality for users, making bearing seals and shields essential components for maximizing the overall efficiency and competitiveness of engineering machinery systems.

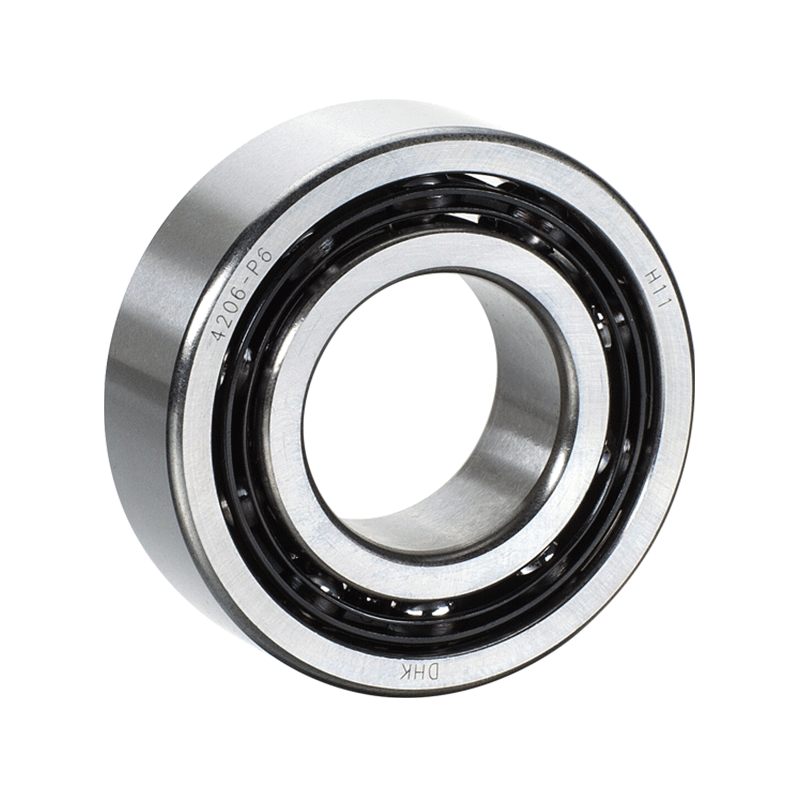

Single Row Tapered Roller Bearings

Single Row Tapered Roller Bearings

English

English Deutsch

Deutsch