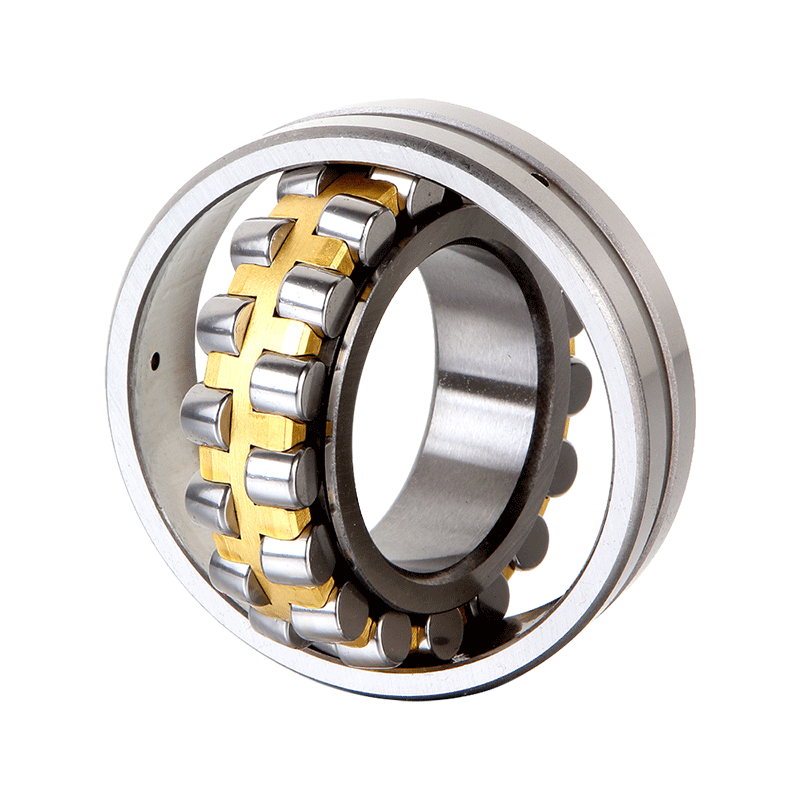

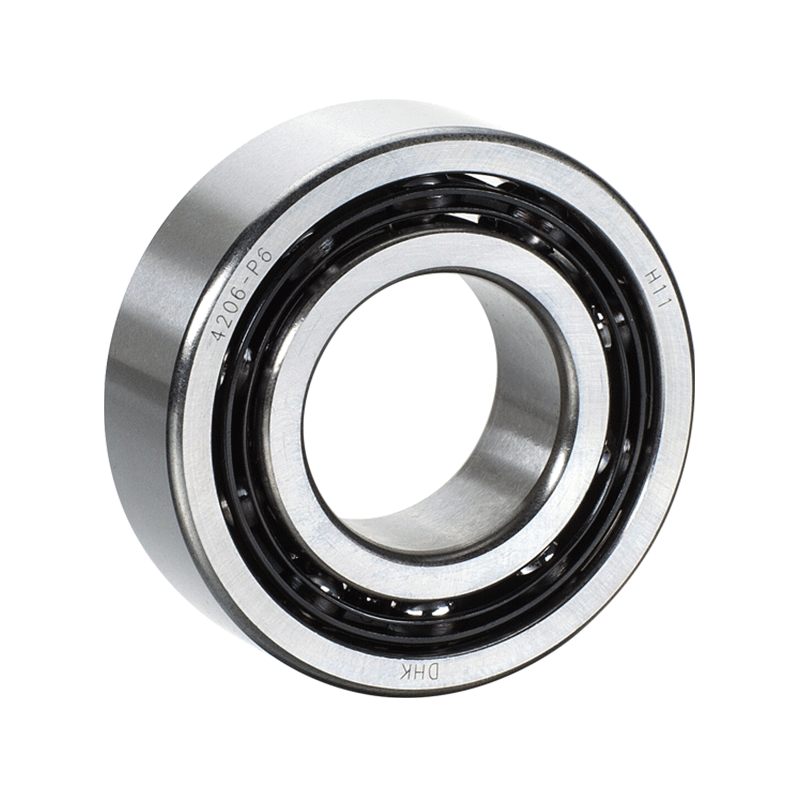

The arrangement of paired single row tapered roller bearings significantly influences their load-carrying capacity and stiffness. Here's how:

Load Distribution: Paired single row tapered roller bearings are strategically arranged to optimize load distribution, a critical aspect of bearing design in industrial applications. By dispersing the load across two bearings instead of one, the pressure on each bearing is reduced, thus minimizing wear and fatigue. This load-sharing characteristic is particularly advantageous in applications with heavy loads or dynamic forces, where even distribution helps prevent premature failure and extends the operational lifespan of the bearings.

Axial Stiffness: Axial stiffness, the ability of the bearing system to resist deformation under axial loads, is paramount for maintaining positional accuracy and stability in machinery. The arrangement of paired bearings is engineered to maximize axial stiffness through precise preloading. By applying a controlled force between the paired bearings, any potential for axial play or movement is eliminated. This preload ensures constant contact between bearing components, effectively bolstering the system's resistance to axial forces and enhancing its overall rigidity.

Radial Stiffness: Radial stiffness, which pertains to the ability of the bearing system to resist deflection under radial loads, is equally crucial for ensuring smooth operation and minimizing vibration. Engineers meticulously design the arrangement of paired bearings to optimize radial stiffness by minimizing misalignment and uneven loading. Through precise alignment and spacing, each bearing is subjected to uniform radial loads, thereby minimizing the risk of localized stress concentrations and promoting consistent performance across the entire bearing system.

Tolerance Stack-Up: Tolerance stack-up refers to the cumulative effect of dimensional variations and manufacturing tolerances within a bearing system. In the context of paired bearings, meticulous attention is paid to minimizing tolerance stack-up to ensure positive alignment and functionality. By controlling factors such as bearing dimensions, mounting tolerances, and assembly procedures, engineers mitigate the risk of misalignment and uneven loading. This meticulous approach not only enhances the overall stiffness of the bearing system but also minimizes the potential for premature wear and failure due to excessive stress concentrations.

Dynamic Load Rating: The dynamic load rating of a bearing system is a key performance metric that indicates its capacity to withstand fluctuating loads over time. Engineers optimize the arrangement of paired bearings to maximize dynamic load rating by carefully considering factors such as bearing spacing, preload levels, and dynamic loading conditions. By ensuring that each bearing operates within its designated load range, manufacturers enhance the system's resilience to dynamic forces and prolong its service life in demanding operating environments.

Paired Single Row Tapered Roller Bearings

English

English Deutsch

Deutsch