Spherical roller bearings offer several key advantages in industrial applications, making them a popular choice for various machinery and equipment. Some of these advantages include:

Self-Alignment: Spherical roller bearings exhibit inherent self-aligning capabilities, allowing them to accommodate angular misalignments between the shaft and housing. This design feature is pivotal in mitigating the detrimental effects of installation inaccuracies, shaft deflections, and other misalignment issues during operation. By virtue of self-alignment, these bearings contribute to enhanced reliability and prolonged operational life in industrial settings.

High Load Capacity: The engineering of spherical roller bearings is optimized to effectively distribute both radial and axial loads, endowing them with a notable capacity to handle heavy and combined loads. This attribute makes them indispensable in applications where varying load types and magnitudes are encountered. The ability to bear substantial loads translates into superior performance and longevity in industrial machinery subjected to diverse loading conditions.

Durability and Longevity: Spherical roller bearings are characterized by a robust and resilient construction, imparting a high degree of durability. This robustness enables the bearings to endure challenging operational environments prevalent in industrial applications, resulting in an extended service life. The consequential reduction in the frequency of replacements and maintenance intervals contributes significantly to cost-effectiveness and operational efficiency.

Versatility: The adaptability of spherical roller bearings renders them suitable for deployment across a spectrum of industrial applications. From mining and construction to heavy machinery and manufacturing processes, these bearings demonstrate versatility by seamlessly integrating into various operational scenarios. This versatility positions spherical roller bearings as a preferred choice for engineers and designers seeking a reliable and adaptable bearing solution.

Reduced Friction and Heat Generation: Advanced design elements, including optimized roller geometry and surface finishes, characterize spherical roller bearings. These features collectively contribute to reduced friction and heat generation during operation. The resultant decrease in energy losses enhances overall efficiency and promotes a cooler operating environment, safeguarding the bearings against premature wear and ensuring sustained performance.

Tolerance to Shock and Vibration: Spherical roller bearings are engineered to withstand shock loads and vibrations encountered in demanding industrial environments. Their robust design, coupled with the ability to absorb and evenly distribute dynamic forces, ensures that these bearings maintain structural integrity and functionality even when subjected to challenging operating conditions. This tolerance to shock and vibration is pivotal for applications where mechanical stresses are inherent.

Ease of Installation and Maintenance: The user-friendly attributes of spherical roller bearings extend to ease of installation and maintenance. Their self-aligning nature simplifies the mounting process, and features such as tapered bore options and adapter sleeves further facilitate straightforward installation and removal. This characteristic, coupled with accessible mounting instructions provided by manufacturers, enhances the user experience and reduces downtime associated with maintenance activities.

Sealing Options: Spherical roller bearings often incorporate a variety of sealing options, ranging from labyrinth seals to double-lip seals. These seals serve the dual purpose of protecting the bearing from contaminants such as dust and moisture while retaining the lubricating grease within the bearing. The availability of diverse sealing solutions allows users to tailor their bearing selection based on the specific environmental challenges posed by their applications.

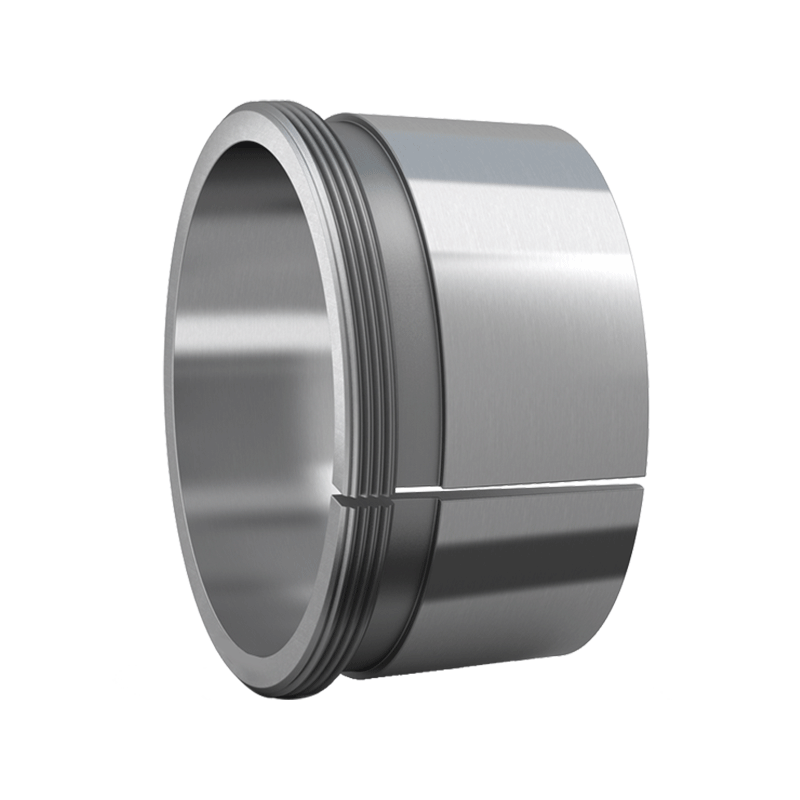

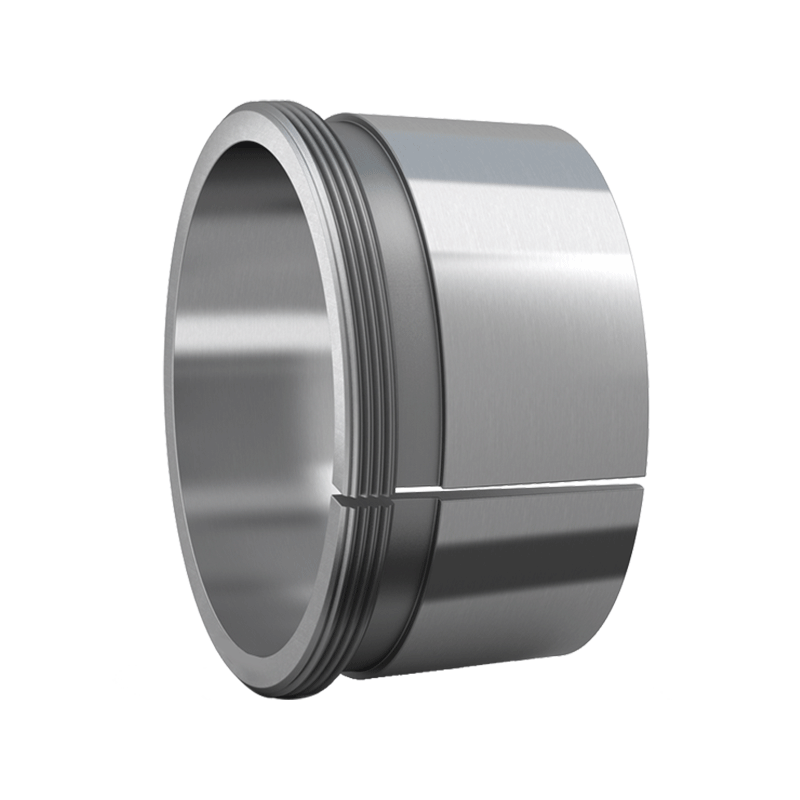

With Withdrawal Sleeve Series

With Withdrawal Sleeve Series

English

English Deutsch

Deutsch