Noise and vibration in double row deep groove ball bearings may be resulting from various factors. Identifying and addressing those problems are important to ensuring smooth operation and maximizing the bearing's lifespan. Here are a few capacity reasons of noise and vibration, in conjunction with mitigation strategies:

1.Insufficient Lubrication:

Cause: Inadequate or mistaken lubrication results in elevated friction between rolling factors and raceways, leading to put on and generating noise and vibration for the duration of operation.

Mitigation: Proper lubrication is critical. Choose a lubricant with the perfect viscosity and load-carrying potential for the particular working conditions. Establish a ordinary maintenance schedule to screen lubricant circumstance and refill or update it as important.

2.Contamination:

Cause: Dust, dust, or other contaminants getting into the bearing compromise the clean operation of rolling elements and raceways, inflicting abrasion and noise.

Mitigation: Implement powerful sealing mechanisms, together with labyrinth seals or lip seals, to shield the bearing from contaminants. Regularly investigate the encircling environment and deploy extra shielding measures, like shields or covers, if needed.

3.Misalignment:

Cause: Misalignment between the internal and outer earrings reasons choppy loading at the bearing elements, leading to noise and vibration.

Mitigation: During installation, make certain particular alignment of the bearing components. If misalignment is inevitable because of the software's nature, don't forget self-aligning double row deep groove ball bearings designed to deal with misalignment.

4.Poor Mounting:

Cause: Incorrect mounting strategies or tools can introduce inner stresses, choppy loading, and misalignment, contributing to noise and vibration.

Mitigation: Adhere to the manufacturer's advocated mounting methods, the use of suitable gear and methods. Utilize specialized mounting equipment, consisting of induction warmers, to acquire even and accurate mounting with out inflicting undue pressure on the bearing additives.

5.Damaged Rolling Elements or Raceways:

Cause: Physical damage, such as scratches or dents, to rolling elements or raceways disrupts the clean rolling movement, ensuing in irregular motion and noise.

Mitigation: Exercise care for the duration of dealing with, garage, and installation to save you harm. Inspect bearings earlier than installation, and if any damage is detected, update the bearing components directly to ensure most beneficial overall performance.

6.Excessive Preload or Clearance:

Cause: Incorrect preload or clearance settings cause expanded friction, producing warmth, noise, and vibration.

Mitigation: Follow producer specs exactly when placing preload or clearance values. Use precision measuring gadgets to gain accurate settings, making sure the bearing operates within the designed parameters.

7.Cage Issues:

Cause: Damage or unsuitable functioning of the cage can motive friction and noise as rolling elements engage with the cage.

Mitigation: Choose bearings with long lasting, amazing cages. Regularly investigate the cage for signs of wear and tear, deformation, or harm. If any issues are located, update the cage right away to maintain proper alignment and spacing of rolling elements.

8.High Operating Speeds:

Cause: High-speed packages make bigger vibration and noise because of the fast movement of rolling factors.

Mitigation: Select bearings especially engineered for excessive-speed operations, considering elements together with cage layout, cloth nice, and lubrication. Implement powerful cooling systems to manipulate the heat generated at excessive speeds, making sure strong bearing overall performance and minimizing noise and vibration.

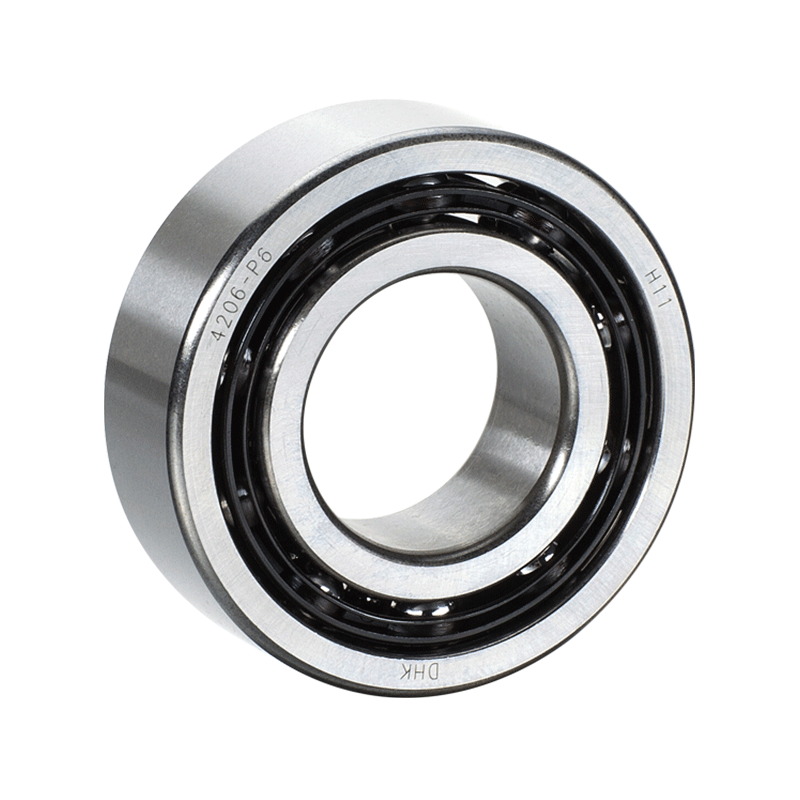

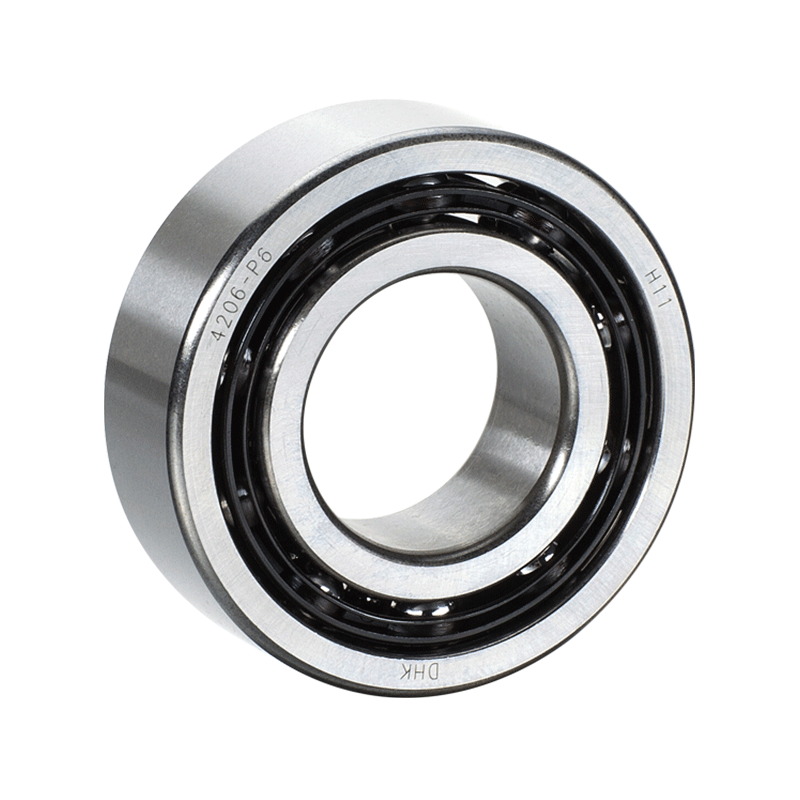

Double Row Deep Groove Ball Bearings

Double Row Deep Groove Ball Bearings

English

English Deutsch

Deutsch