There are specific considerations when selecting bearings for high-load agricultural machinery like tractors and combines. High-load agricultural machinery operates under challenging conditions, including heavy loads, varying speeds, and often uneven terrain. When choosing bearings for such equipment, several factors need to be taken into account:

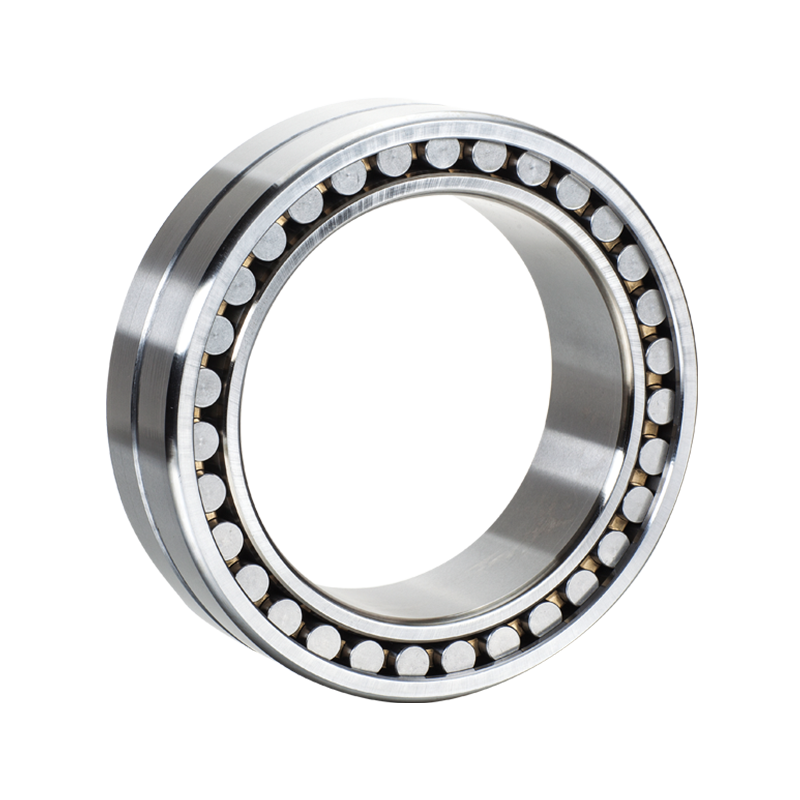

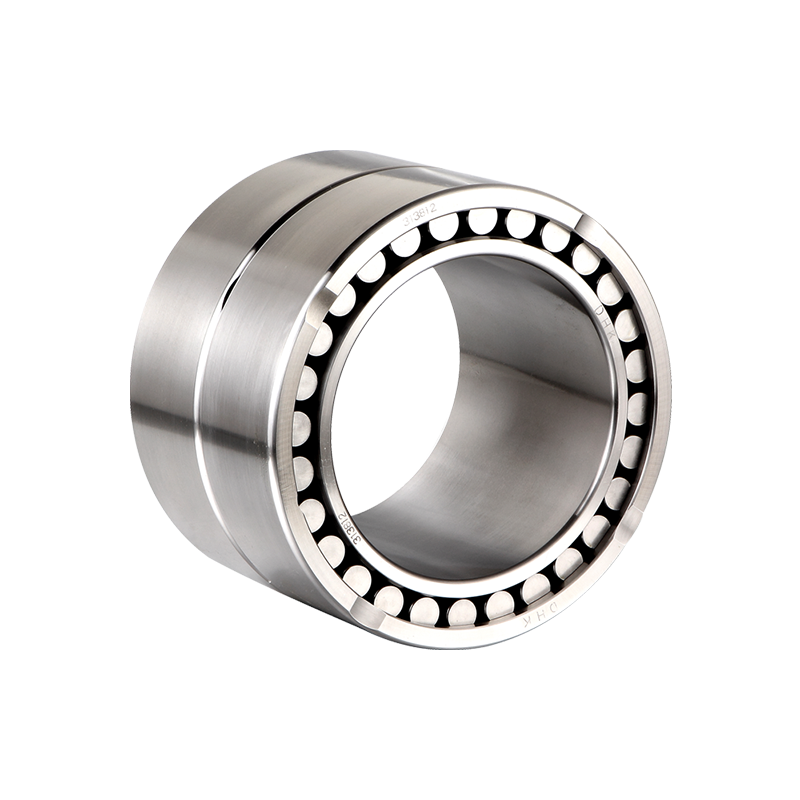

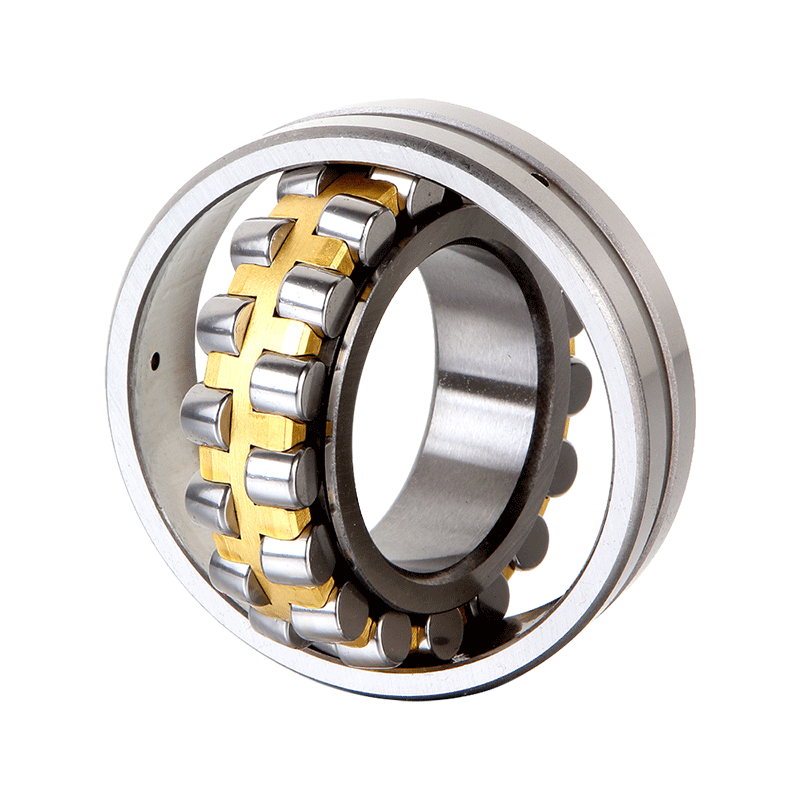

1.Load Capacity: High-load agricultural machinery, such as tractors and combines, exerts substantial forces during operation. Bearings with a high load-carrying capacity, often achieved through larger and more robust rolling elements, are crucial. Choosing bearings with the appropriate load capacity ensures they can withstand the heavy loads without premature wear or failure.

2.Durability: Bearings in high-load applications must be exceptionally durable to withstand the constant stress and wear. Manufacturers often employ hardened steel or specialized alloys that undergo rigorous heat treatments to enhance their durability and resistance to wear, ensuring a longer operational lifespan.

3.Lubrication: Adequate and effective lubrication is paramount to minimize friction and dissipate heat in high-load scenarios. Lubrication systems, such as oil bath or circulating systems, are often integrated to ensure a continuous supply of lubricant to critical bearing components. Proper lubrication prevents overheating, reduces wear, and maintains the bearings' integrity over time.

4.Seals and Shields: Bearings in high-load agricultural machinery are exposed to various contaminants, including dust, dirt, moisture, and agricultural chemicals. Effective seals and shields, often made from rubber or specialized materials, are implemented to protect the bearings from these contaminants. Seals and shields not only prevent damage but also extend the bearing's operational life by maintaining a clean internal environment.

5.Heat Dissipation: High-load applications generate significant heat due to friction and continuous operation. Bearings designed for such machinery incorporate features like cooling fins, special heat-resistant materials, or innovative designs that facilitate efficient heat dissipation. Proper heat management ensures the bearings operate within their temperature limits, preventing thermal damage and maintaining performance.

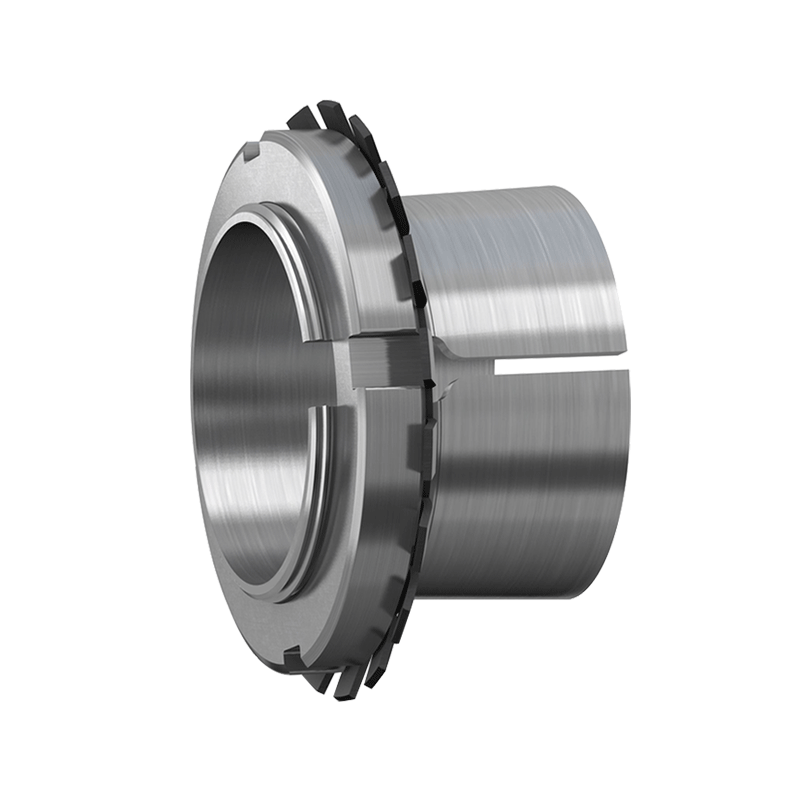

6.Alignment and Tolerance: Precise alignment during installation and adherence to strict tolerance standards are critical. Misalignment, even in microscopic measurements, can lead to uneven loading and premature wear. High-precision manufacturing processes and meticulous installation techniques are employed to ensure optimal alignment, thereby maximizing the bearings' efficiency and lifespan.

7.Material Selection: High-quality materials are carefully chosen for manufacturing bearings in high-load agricultural machinery. These materials, often high-grade steel or advanced alloys, undergo stringent quality control measures. The selected materials provide the necessary strength, hardness, and resilience, enabling the bearings to endure the heavy loads and harsh operating conditions characteristic of agricultural equipment.

8.Vibration Resistance: High-load agricultural machinery is prone to vibrations caused by various factors, including uneven terrain and mechanical imbalances. Bearings must be designed to absorb and resist these vibrations. Advanced bearing designs and technologies, such as cage optimization and enhanced rolling element geometries, are employed to minimize the effects of vibrations, preventing fatigue failure and ensuring long-term reliability.

9.Easy Maintenance: Bearings should be designed for accessibility and ease of maintenance. Components that are easily accessible facilitate timely inspections, lubrication, and replacements as needed. Manufacturers consider practical aspects of maintenance, such as bearing placement within the machinery, to minimize downtime during repairs, ensuring that the equipment remains operational and productive.

10.Corrosion Resistance: Agricultural environments expose bearings to corrosive elements, including fertilizers, pesticides, and moisture. Corrosion-resistant coatings, such as zinc or nickel plating, are applied to the bearing surfaces. Additionally, bearings made from stainless steel or other corrosion-resistant materials are used to enhance their resistance to chemical corrosion, ensuring prolonged durability in challenging agricultural conditions.

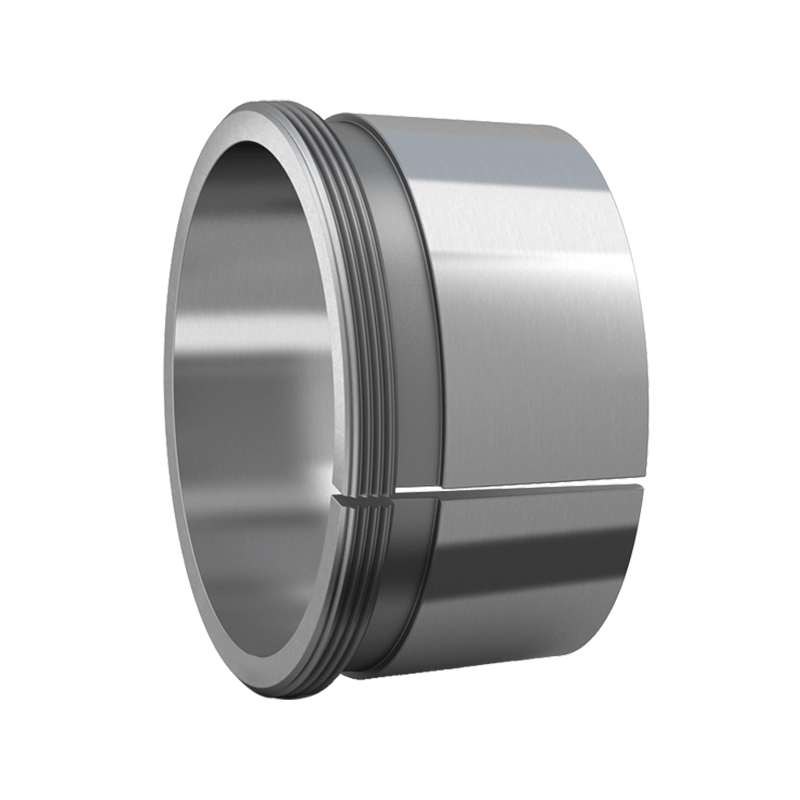

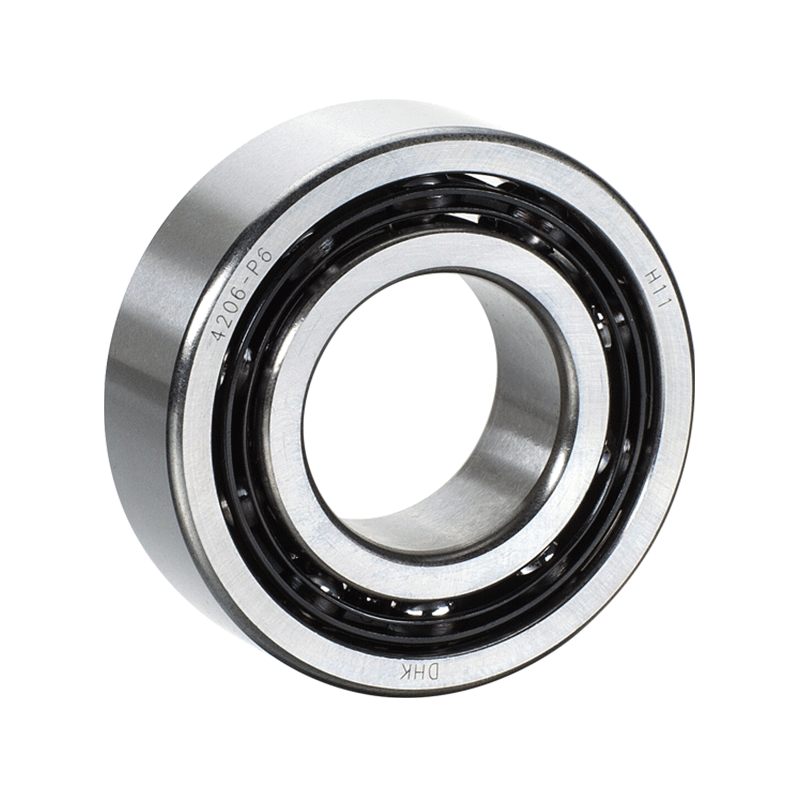

Radial Insert Ball Bearings With Eccentric Locking Collar

Radial Insert Ball Bearings With Eccentric Locking Collar

English

English Deutsch

Deutsch