Bearing sealing plays a crucial role in protecting agricultural machinery bearings from contaminants and ensuring optimal performance. Here are several key aspects:

Contaminant Exclusion: Precision Agriculture Considerations: In precision agriculture, where machinery operates in close proximity to crops and soil, the significance of effective sealing is heightened. Seals, meticulously designed and engineered, create an impermeable barrier against minute particulate matter, safeguarding intricate components from abrasion. This meticulous exclusion of contaminants not only ensures the longevity of bearings but also plays a pivotal role in maintaining the precision required for modern farming practices.

Lubrication Retention: Criticality of Lubrication Control: Agricultural machinery, subject to varying loads and operating conditions, demands a meticulous approach to lubrication. Seals, beyond merely serving as barriers, function as custodians of lubricating mediums. Their role in retaining a consistent, controlled lubrication environment becomes critical in high-load scenarios. The ability to sustain an optimal lubrication film is not just a preventive measure against wear; it's a proactive strategy for optimizing operational efficiency, reducing energy consumption, and extending the service life of the machinery.

Environmental Protection: Harsh Environment Endurance: Agricultural machinery faces a relentless onslaught of environmental challenges. Seals, crafted from materials fortified for endurance, stand resilient against prolonged exposure to sunlight, heavy rainfall, and temperature fluctuations. The meticulous engineering of these seals ensures that the bearings within remain impervious to the corrosive impact of the elements. This endurance is not just a testament to material science but a strategic shield preserving the structural integrity of bearings, even in the harshest of environments.

Extended Maintenance Intervals: Operational Efficiency: The extension of maintenance intervals isn't merely a convenience; it's a strategic imperative in agricultural operations. In the dynamic landscape of planting and harvesting seasons, where downtime equates to lost opportunities, sealed bearings emerge as silent contributors to operational efficiency. By reducing the frequency of required maintenance, these bearings provide a continuous operational window, allowing farmers to capitalize on critical periods without the disruptions associated with frequent equipment checks and adjustments.

Prevention of Water and Chemical Ingress: Chemical Compatibility: The agricultural terrain is not just dusty and muddy; it's chemically charged with fertilizers, pesticides, and agrochemicals. Seals, engineered with an acute understanding of chemical compatibility, act as guardians against invasive chemical agents. They form an impenetrable barrier, preventing corrosive interactions that could compromise the integrity of bearings. In this chemical battleground, sealed bearings aren't just passive components; they're frontline defenders, ensuring the structural robustness of critical machinery elements.

Impact on Reliability and Uptime: Operational Continuity: The reliability of agricultural machinery isn't a luxury; it's a prerequisite. Sealed bearings are the unsung heroes of operational continuity. By contributing to extended bearing life, they mitigate the risk of unexpected failures that could disrupt the relentless rhythm of agricultural operations. In a sector where every hour counts, and downtime translates to tangible losses, the reliability conferred by sealed bearings is a strategic advantage, ensuring that machinery performs predictably and consistently throughout demanding operational cycles.

Ease of Maintenance: Simplified Maintenance Procedures: The simplicity of maintenance procedures isn't just a convenience for farmers; it's a deliberate design philosophy embedded in sealed bearings. With reduced vulnerability to contaminants and an inherent capacity for lubrication retention, these bearings redefine the maintenance landscape. Farmers and equipment operators are liberated from the shackles of constant vigilance. The reduced frequency of monitoring and adjustments doesn't just save time; it empowers those on the field to focus on productive tasks, elevating the operational efficiency of the entire farming enterprise.

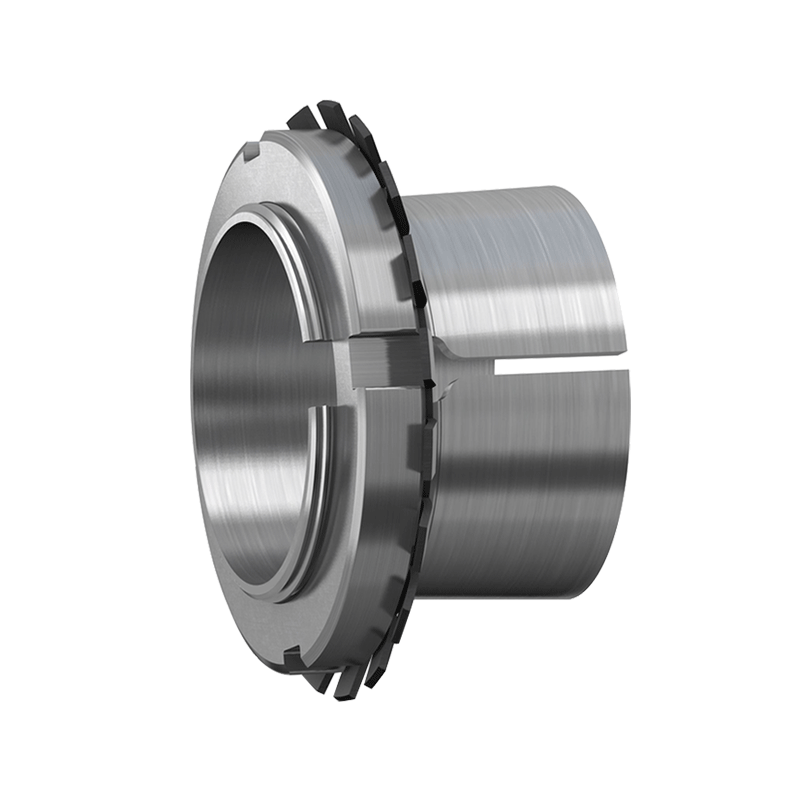

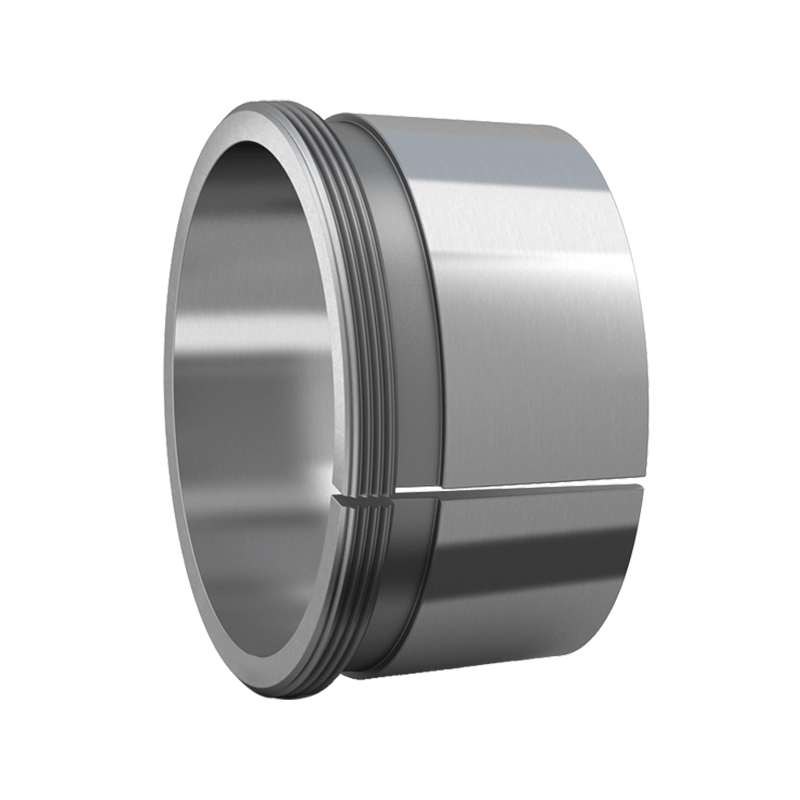

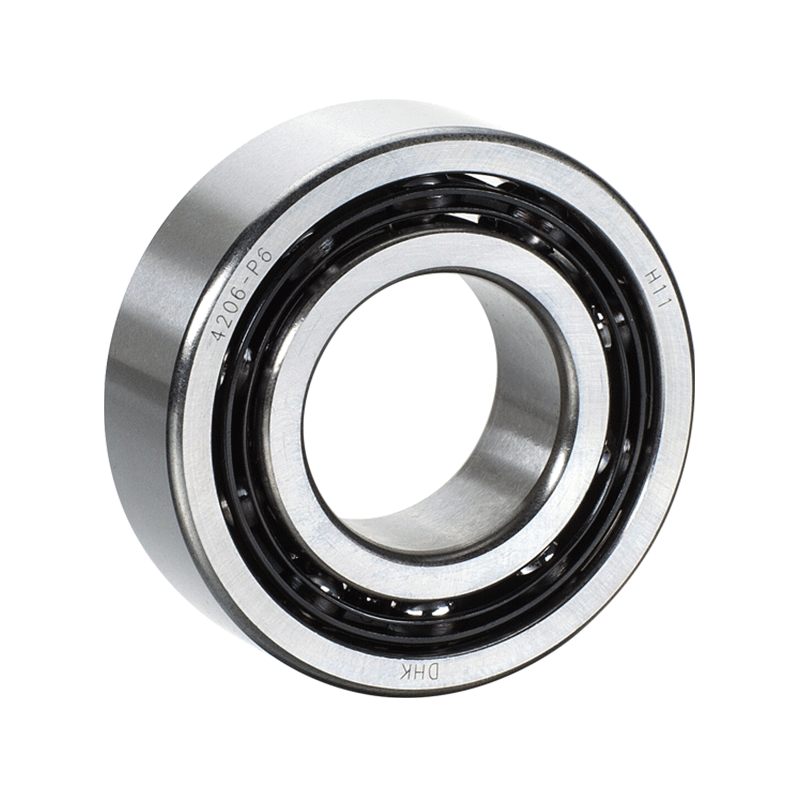

Radial Insert Ball Bearings Without Eccentric Locking Collar

Radial Insert Ball Bearings Without Eccentric Locking Collar

English

English Deutsch

Deutsch