Reducing Friction: Lubricants serve as a boundary layer between the rolling elements (balls or rollers) and the raceways of the bearing. This layer, often only a few micrometers thick, prevents direct metal-to-metal contact. Without lubrication, the high friction between these surfaces would lead to rapid wear and increased energy consumption. By minimizing friction, lubricants ensure smoother rotation of the bearing, which is vital for the efficient operation of automotive systems.The choice of lubricant viscosity and additives can further optimize friction reduction based on specific operating conditions, such as temperature and load.

Heat Dissipation: The friction generated within a bearing assembly produces heat, which, if not properly managed, can lead to detrimental effects. Lubricants with high thermal conductivity and heat-carrying capacity absorb this heat and transport it away from critical bearing surfaces. This prevents localized overheating, which could otherwise degrade the lubricant, compromise its protective properties, and ultimately lead to bearing failure. Lubricants with excellent thermal stability maintain their viscosity and lubricating properties over a wide range of temperatures, ensuring consistent performance under varying operating conditions.

Preventing Corrosion: Automotive bearings are constantly exposed to environmental factors that can accelerate corrosion, such as moisture, humidity, road salts, and chemical pollutants. Lubricants create a protective barrier on bearing surfaces, shielding them from corrosive agents and inhibiting the formation of rust and oxidation. Certain lubricants contain corrosion inhibitors and antioxidants that provide additional protection against chemical degradation, extending the service life of the bearing and preserving its structural integrity in harsh operating environments.

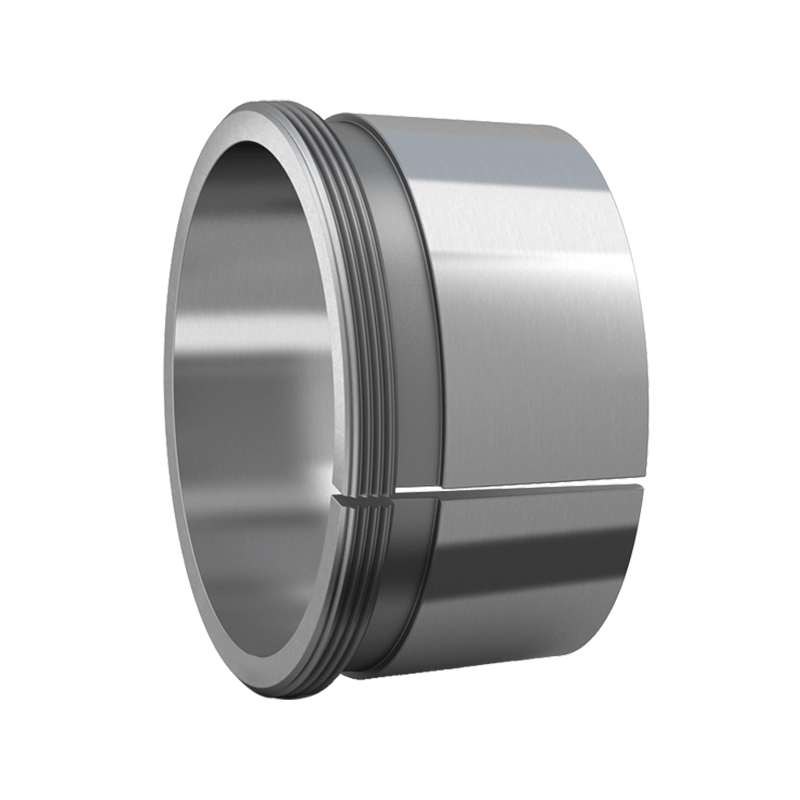

Sealing Effect: Sealed bearings are pre-greased and equipped with integrated seals or shields that prevent the ingress of contaminants into the bearing cavity. These seals act as a physical barrier, blocking dirt, dust, water, and other foreign particles from entering the bearing assembly. The lubricant inside sealed bearings is retained more effectively, reducing the need for frequent re-lubrication and minimizing the risk of lubricant leakage. By maintaining a clean and contamination-free environment, sealed bearings exhibit superior performance and reliability, particularly in automotive applications where exposure to abrasive elements is common.

Load Distribution: Lubricants play a critical role in distributing applied loads evenly across the bearing surfaces. As rolling elements move within the bearing assembly, lubricants form a hydrodynamic or elastohydrodynamic film that separates the contacting surfaces and redistributes the applied loads. This reduces stress concentrations and minimizes the risk of localized wear and fatigue failure. Lubricants with extreme pressure additives enhance the load-carrying capacity of bearings, allowing them to withstand higher loads and operate more efficiently under demanding conditions encountered in automotive applications.

Noise Reduction: In addition to minimizing friction and wear, effective lubrication helps dampen vibrations and reduce noise generated during bearing operation. As rolling elements traverse the raceways, lubricants act as a cushioning medium, absorbing shocks and attenuating mechanical vibrations. This results in quieter and smoother operation of the bearing, enhancing the comfort and ride quality of the vehicle. The choice of lubricant viscosity and additives can influence noise generation and propagation, allowing automotive manufacturers to optimize bearing performance and minimize noise emissions in their vehicles.

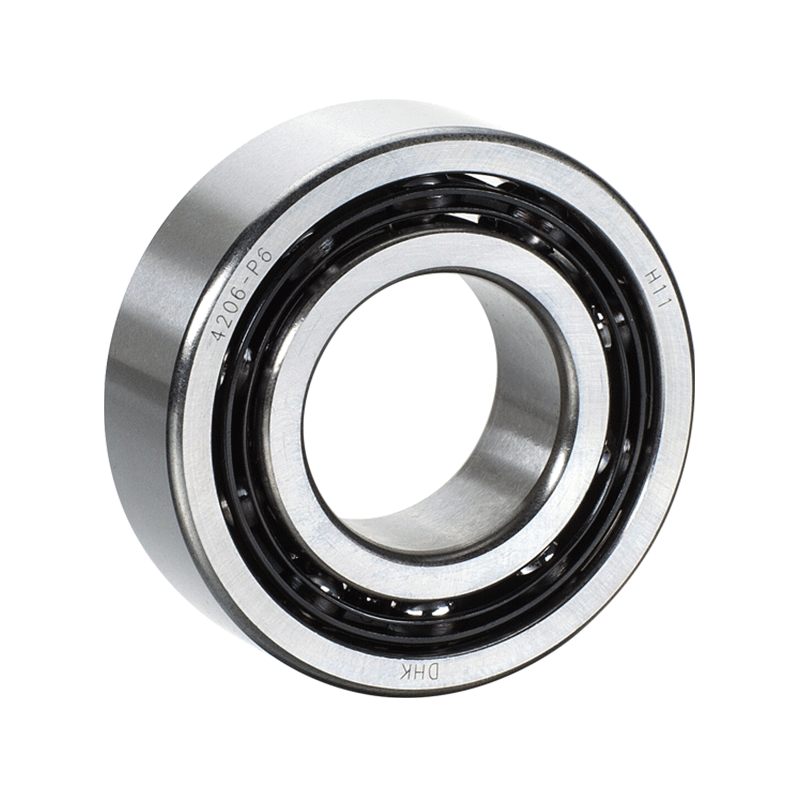

Four Point Contact Ball Bearings

English

English Deutsch

Deutsch