Rolling mill bearings play a critical role in the overall performance and efficiency of rolling mills, which are used in industries like steel, aluminum, and metal processing. Here's how rolling mill bearings contribute to these aspects:

1.Reduced Friction and Energy Consumption:

Rolling mill bearings are engineered with precision to minimize friction between their moving parts. By reducing friction, these bearings help to decrease energy consumption and heat generation within the rolling mill machinery. This translates to improved efficiency, as less energy is lost as waste heat, and more energy is available for productive work.

2.Smooth Operation:

Rolling mill bearings facilitate smooth and consistent rotation of key components such as rolls and guides. Smooth operation is essential for preventing vibrations and jarring, which can lead to damage or irregularities in the rolled material. A lack of vibrations also contributes to the longevity of the machinery and its components.

3.Higher Precision and Accuracy:

Precision rolling mill bearings maintain accurate positioning of the rolls and other components. This precise alignment is critical for achieving consistent product dimensions, tight tolerances, and desired surface finishes. By maintaining such precision, these bearings ensure that the final product meets quality standards.

4.Reduced Downtime:

Reliable rolling mill bearings that are selected based on the specific application and are properly maintained can lead to reduced downtime. Bearings that are less prone to failures minimize unexpected shutdowns, allowing the mill to operate consistently and meet production targets. Reduced downtime positively impacts the mill's overall productivity and efficiency.

5.Optimized Load Distribution:

Rolling mill bearings are designed to evenly distribute loads, both radially and axially, across the rolling elements. This even distribution of loads prevents localized stress concentrations, which can lead to premature bearing wear or failure. A balanced load distribution ensures that the bearings function optimally over extended periods, contributing to efficient and trouble-free mill operation.

6.Improved Product Quality:

Precise and consistent rolling processes, made possible by well-functioning bearings, result in higher-quality final products. Accurate positioning of rolls and components ensures that the product's dimensions, surface finish, and mechanical properties meet desired specifications. This quality enhancement is vital for maintaining customer satisfaction and market competitiveness.

7.Enhanced Safety:

Rolling mill bearings contribute to a safer working environment by minimizing the risk of sudden machinery breakdowns or failures. When bearings are functioning properly, the likelihood of accidents caused by malfunctioning equipment is reduced. This factor is critical for the safety and well-being of mill operators and workers.

8.Higher Rolling Speeds:

Advanced rolling mill bearing technology allows mills to operate at higher speeds without compromising stability. Increased rolling speeds can lead to greater productivity and throughput, contributing to overall mill efficiency. The ability to achieve higher speeds while maintaining quality and safety standards enhances the mill's competitive edge.

9.Extended Maintenance Intervals:

Bearings designed for durability and longevity can significantly extend the time between maintenance intervals. This reduced maintenance frequency means less downtime for servicing and repairs. Extended maintenance intervals positively impact overall mill efficiency by maximizing operational uptime.

10.Reduced Maintenance Costs:

Properly selected rolling mill bearings, along with regular monitoring, lubrication, and preventive maintenance practices, can lower overall maintenance costs. Bearings that are less prone to failures or wear reduce the need for frequent replacements and repairs, translating to cost savings over the long term.

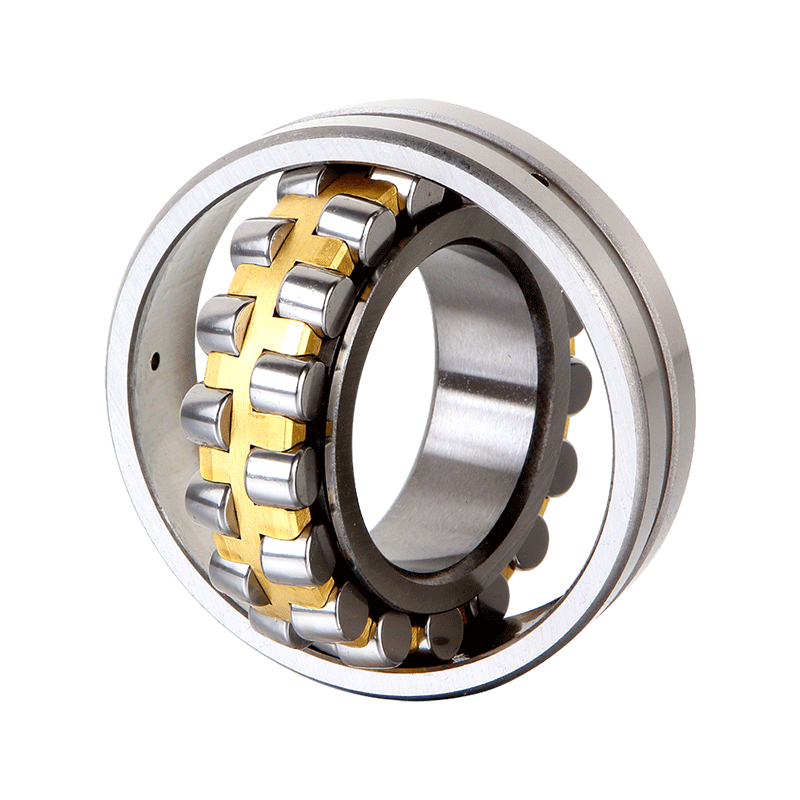

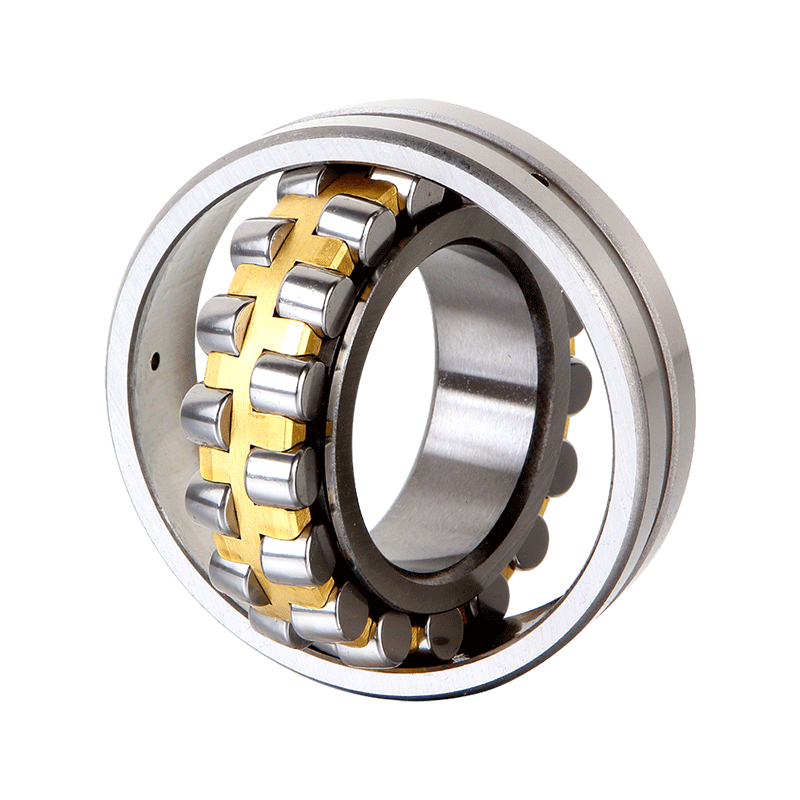

Normally spherical roller bearings are non- separable double-row radial bearings, produced in open design as standard. On request, DHK can also design and produce single row spherical roller bearings or split outer ring spherical roller bearings.

English

English Deutsch

Deutsch