Motor bearings are mechanical components used in electric motors and other rotating machinery to facilitate smooth and efficient operation. Their primary function in a motor system is to support and guide the rotating shaft or rotor while minimizing friction and reducing wear and tear. Motor bearings enable the following key functions:

1.Shaft Support:

Motor bearings serve as essential supports for the motor's rotating shaft or rotor. They are strategically positioned within the motor housing to maintain precise alignment and control the movement of the shaft. This support is crucial to prevent excessive vibration, misalignment, and premature wear of the motor's internal components. Without proper shaft support, the motor's performance and longevity would be compromised.

2.Load Carrying:

Motor bearings are designed to bear the weight of the rotor, stator, and any attached loads or equipment. They are engineered to withstand both axial and radial loads, ensuring that the rotating elements remain in their designated positions. Effective load-carrying capacity is critical to prevent shaft deflection and maintain the integrity of the motor's internal components.

3.Friction Reduction:

Bearings employ rolling elements, such as balls or rollers, to minimize the friction between the rotating shaft and the stationary bearing housing. This reduction in friction is essential for achieving efficient motor operation. Lower friction levels translate to reduced energy consumption, heat generation, and wear on the bearing surfaces, all of which contribute to improved motor efficiency and longevity.

4.Heat Dissipation:

During motor operation, heat is generated due to friction and electrical losses. Motor bearings play a significant role in heat dissipation by allowing the shaft to rotate smoothly. Proper heat dissipation prevents the motor from overheating, which can lead to insulation degradation and reduced motor life. Additionally, some bearings incorporate cooling features or materials to enhance heat dissipation in high-temperature environments.

5.Alignment Maintenance:

Motor bearings contribute to maintaining the alignment of the rotor and stator within the motor. Precise alignment is critical for efficient power transmission, reduced vibration, and prolonged motor life. Bearings help counteract any forces or moments that may disrupt this alignment, ensuring that the motor continues to operate smoothly and reliably.

6.Noise Reduction:

In industrial and commercial applications, noise reduction is often a critical consideration. Bearings that operate smoothly and efficiently contribute to quieter motor operation. Excessive noise can be a sign of bearing wear, misalignment, or inadequate lubrication, all of which can be detrimental to the motor's performance and service life. Properly functioning bearings help mitigate these noise issues.

7.Seal Protection:

Some motor bearings are equipped with seals or shields to protect the internal components from contaminants, moisture, and dust. These protective features help maintain the integrity of the bearing surfaces and lubrication, reducing the risk of premature failure and extending the overall reliability of the motor system, especially in harsh or dirty environments.

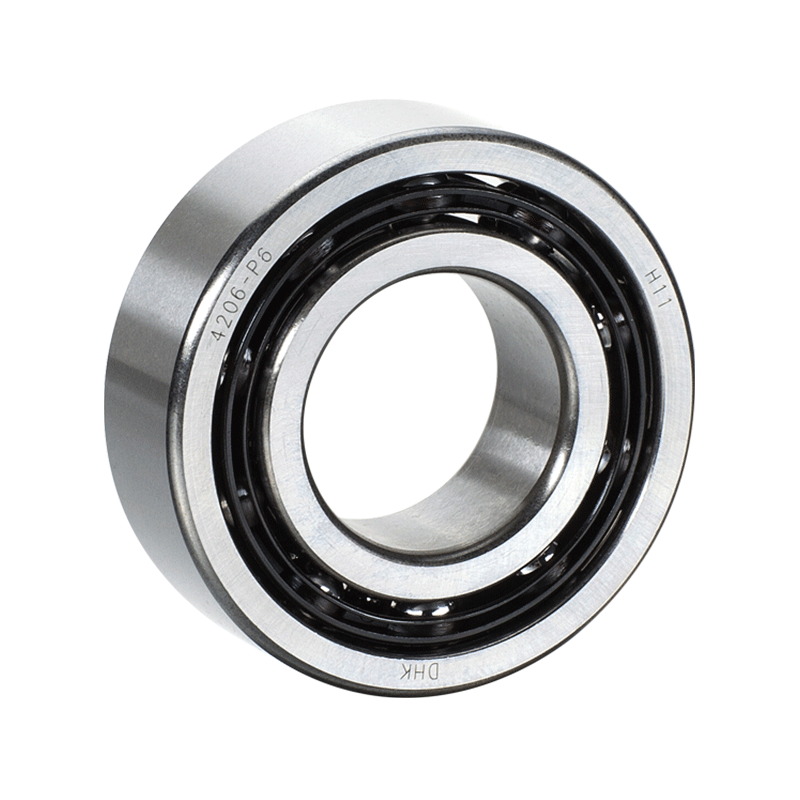

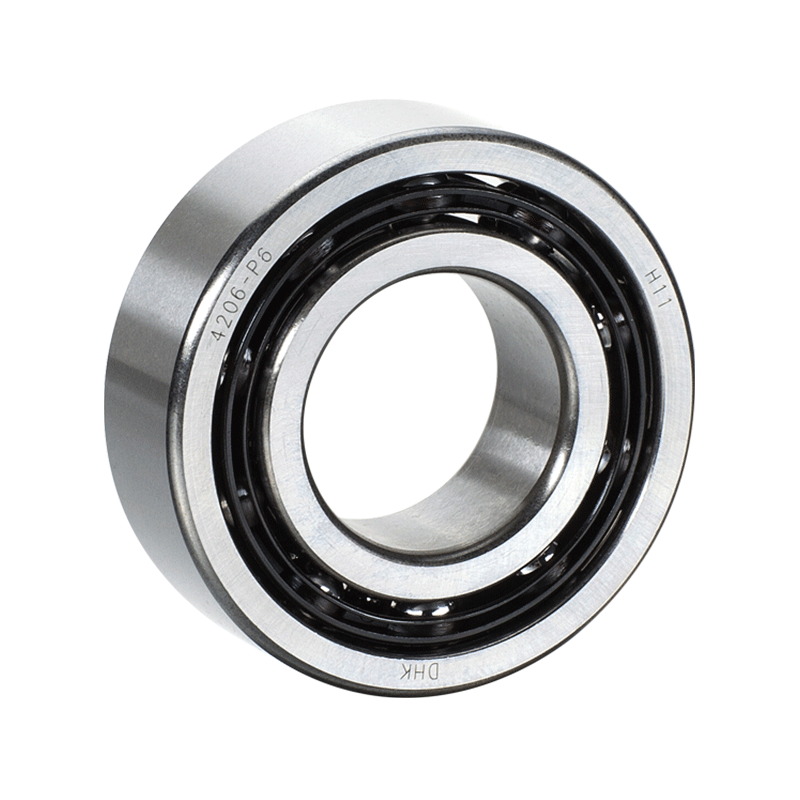

Double row deep groove ball bearings have two basil design variants, one is with filling slot, the other is without filling slots.

DHK double row deep groove ball bearings have the latest design (suffix B), without filling slots. Thus they are able to accommodate axial force equally well in both directions.

English

English Deutsch

Deutsch