Seals and shields in engineering machinery bearings play a crucial role in protecting the bearings from contaminants and maintaining their efficiency by providing a physical barrier between the internal components of the bearing and the external environment. Here's how they contribute to the performance and longevity of engineering machinery bearings:

1.Contaminant Prevention:

Seals and shields act as mechanical barriers designed to stringent tolerances, effectively excluding contaminants from the bearing's internal components. The ingress of foreign particles, such as dust and debris, can compromise the dimensional integrity of the bearing surfaces, leading to premature wear and failure. By employing specialized seals and shields, engineers ensure the sustained integrity of the bearing, preserving its operational efficiency.

2.Lubrication Retention:

Proper lubrication is fundamental to the longevity and performance of engineering machinery bearings. Seals and shields function as integral elements of a closed lubrication system. They encapsulate the lubricating medium within the bearing, preventing leakage and ensuring a consistent, adequate supply of lubricant to the rolling elements. This meticulous control of lubrication minimizes friction, heat, and wear, optimizing the bearing's operational lifespan and efficiency.

3.Corrosion Protection:

Engineering machinery bearings are often subjected to challenging environments where moisture and corrosive agents pose significant threats. Seals and shields are engineered from materials resistant to corrosion, forming a robust defense against oxidation and rust formation. By creating a hermetic seal, these components shield the bearing from the detrimental effects of moisture, guaranteeing its structural integrity and operational reliability even in adverse conditions.

4.Preserving Precision:

Precision engineering machinery demands an exceptional degree of accuracy in its components. Seals and shields play a pivotal role in maintaining this precision by preventing even minuscule particles from infiltrating the bearing assembly. By ensuring the unhindered movement of rolling elements, these protective components safeguard the machinery's accuracy, thereby upholding the overall efficiency and reliability of the equipment.

5.Reduction of Friction:

Seals and shields are crafted with materials optimized for low-friction characteristics. Their design minimizes surface contact and frictional resistance, thereby contributing to the overall energy efficiency of the machinery. By reducing frictional losses, these components enhance the machinery's performance, promoting smoother operation and conserving energy resources.

6.Noise Reduction:

The meticulous engineering of seals and shields extends to noise reduction mechanisms. Through the incorporation of vibration-damping materials and precise design, these components attenuate the noise generated during the bearing's operation. This noise reduction is of paramount importance, especially in applications where noise pollution must be minimized, ensuring the machinery's compliance with stringent regulatory standards.

7.Longevity:

By preventing contaminants, retaining lubrication, and preserving precision, seals and shields substantially enhance the bearing's longevity. The robust defense they provide against wear, corrosion, and fatigue ensures the bearing's extended service life, reducing downtime and maintenance costs. Bearings equipped with meticulously designed seals and shields offer unparalleled longevity, making them indispensable in critical engineering applications.

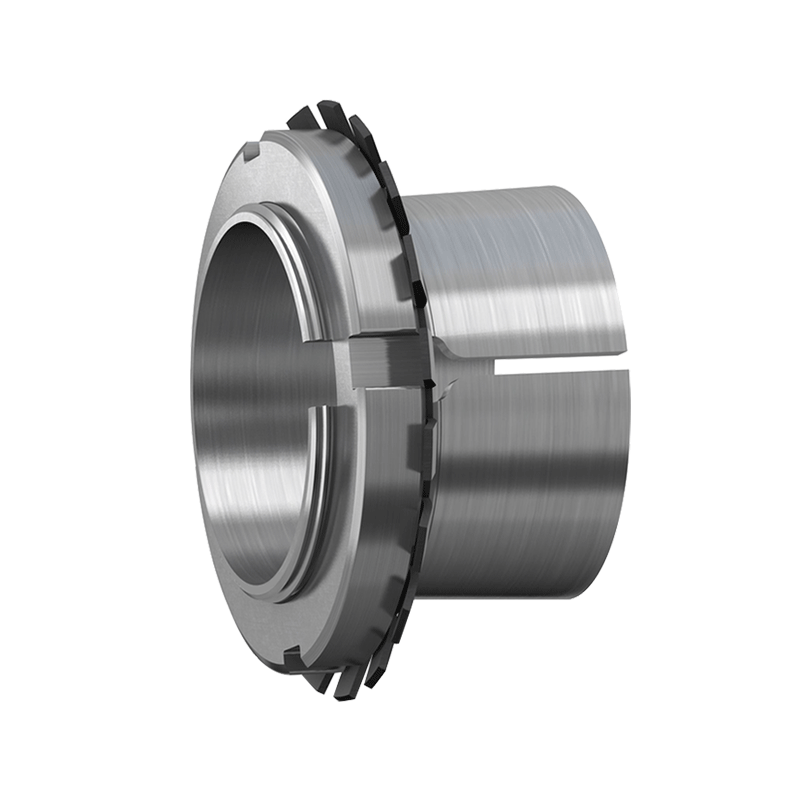

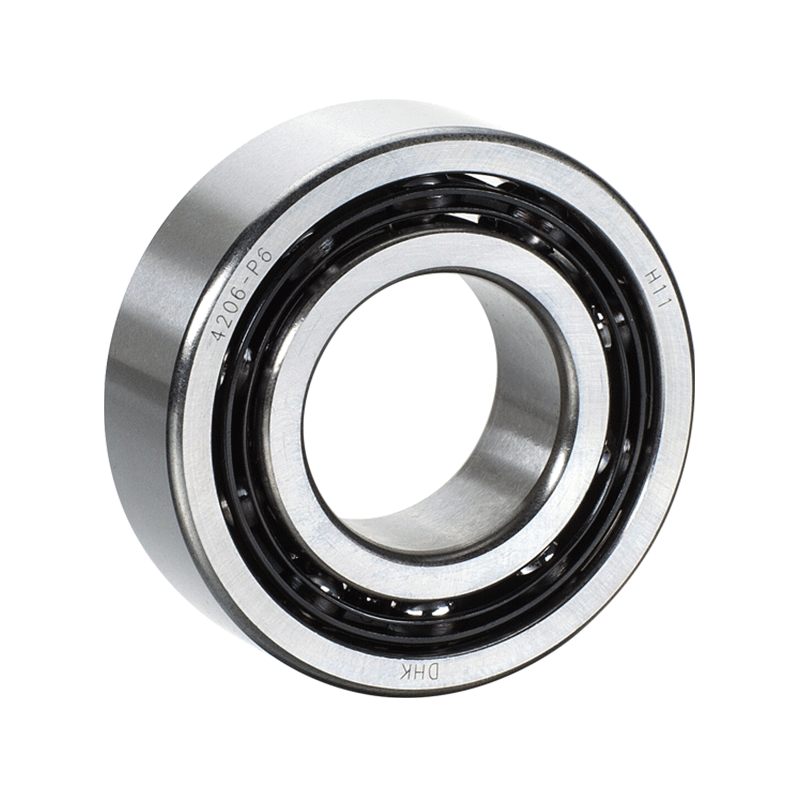

Paired Single Row Tapered Roller Bearings

Because tapered roller bearings can only bear unidirectional axial load, they are often used in pairs. DHK can provide paired single row tapered roller bearings on demand, face to face pairing (suffix DF), back to back pairing (suffix DB), and series (suffix DT).

English

English Deutsch

Deutsch